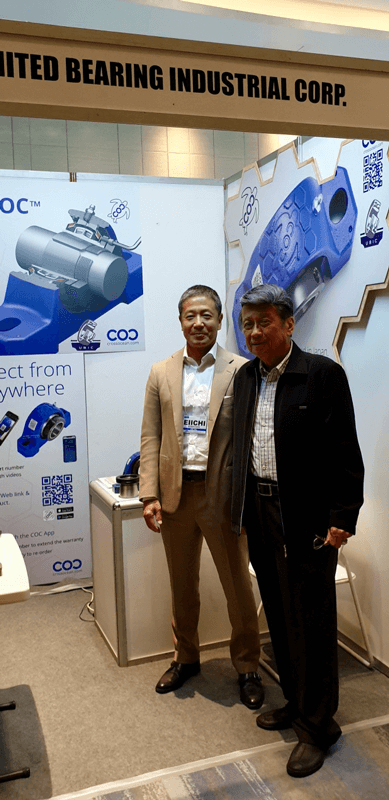

Feedback from Philippines

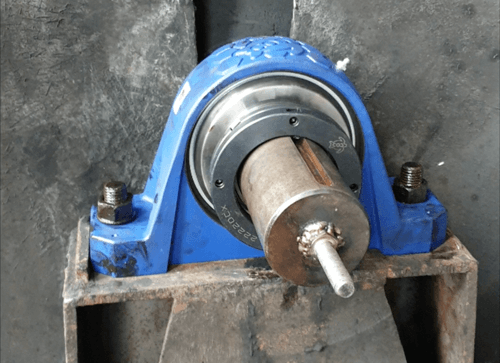

This video is from our distributor in Philippines.

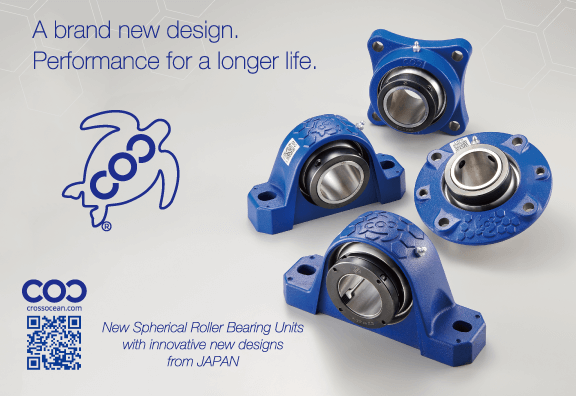

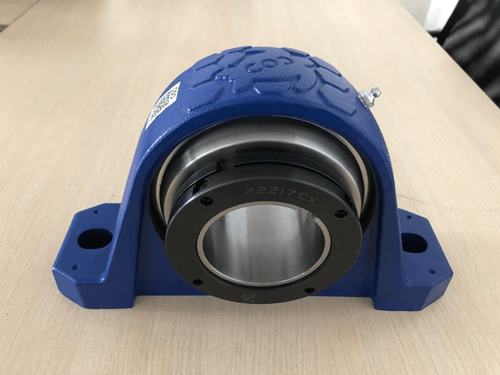

“A usual day of dismounting, mounting and alignment. Finished in just a couple of hours, we still have spare time for more activities” Jerry – Maintenance Supervisor

They spent half a day for this befoe with 2 piece Plummer Block.