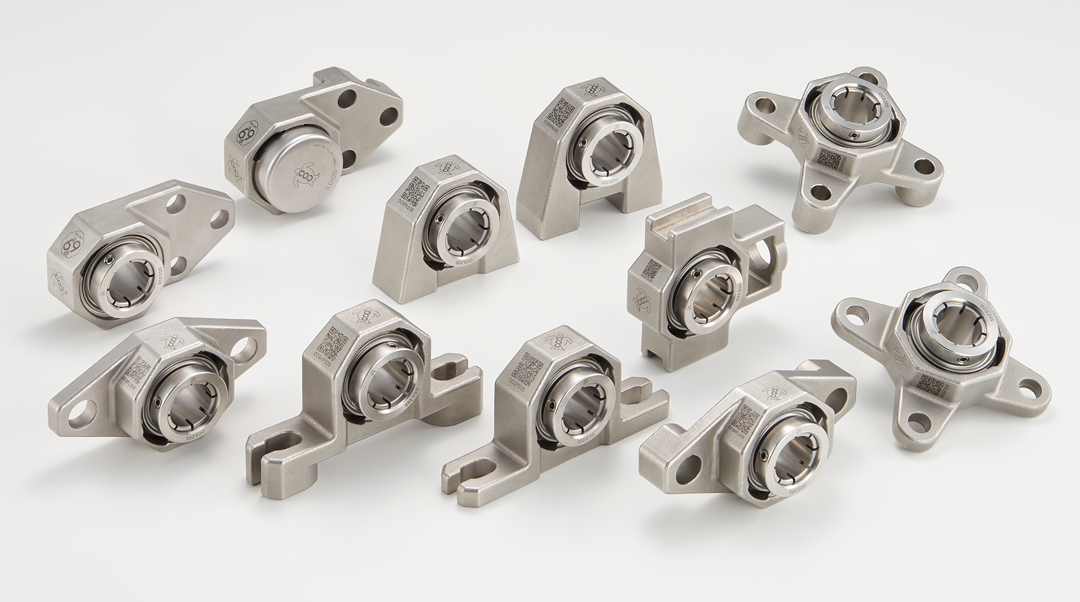

Saniline

New stainless ball bearing units for washdown applications, Saniline is launched.

IP69 certified lubricated for life sealing system with new OCCLOC™ concentric locking system allows the ultimate in food safety.

100 percent compatible with SAF units

We use the standard adapter sleeve for CROSSLOC™ and this is why our unitized SAF units are 100% compatible with standard SAF plummer block units. Our competitors use a one size smaller insert for their unitized SAF plummer blocks. Their adapter mount inserts are compatible with setscrew locking inserts. The standard 22200K inserts used in the SAF plummer block are one size bigger than straight bore inserts to accommodate the adapter. Since the insert being used is smaller, the load rating of their units is less than the traditional SAF plummer block.

SAF Compatible Unitized Units - Smaller Bearing than Standard SAF is used in the red area.

CROSSLOC™ CXC

Cylindrical bore (setscrew straight bore insert) equivalent

CROSSLOC™ CXC bearing is the same O.D. size version as CS setscrew lock cylindrical bore inserts. It’s one size smaller O.D. than CROSSLOC™ CX inserts for SN & SAF housings. We use our original thinner wall lower angle tapered sleeve for CROSSLOC™ CXC to be compatible with dimensions of CS setscrew lock inserts. The system is very simple as CROSSLOC™ CX as tightening cap screws to lock and loosening cap screws to unlock.

SAF units

SAF

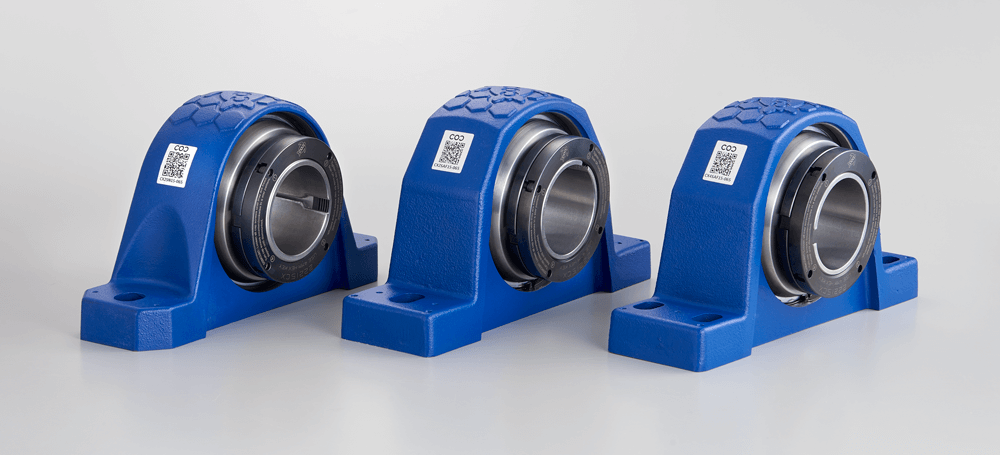

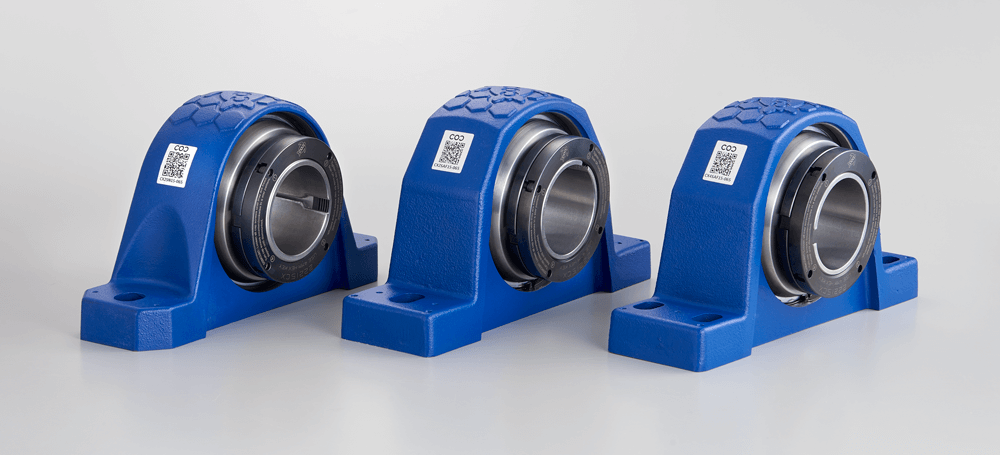

CX2SAF

CX4SAF

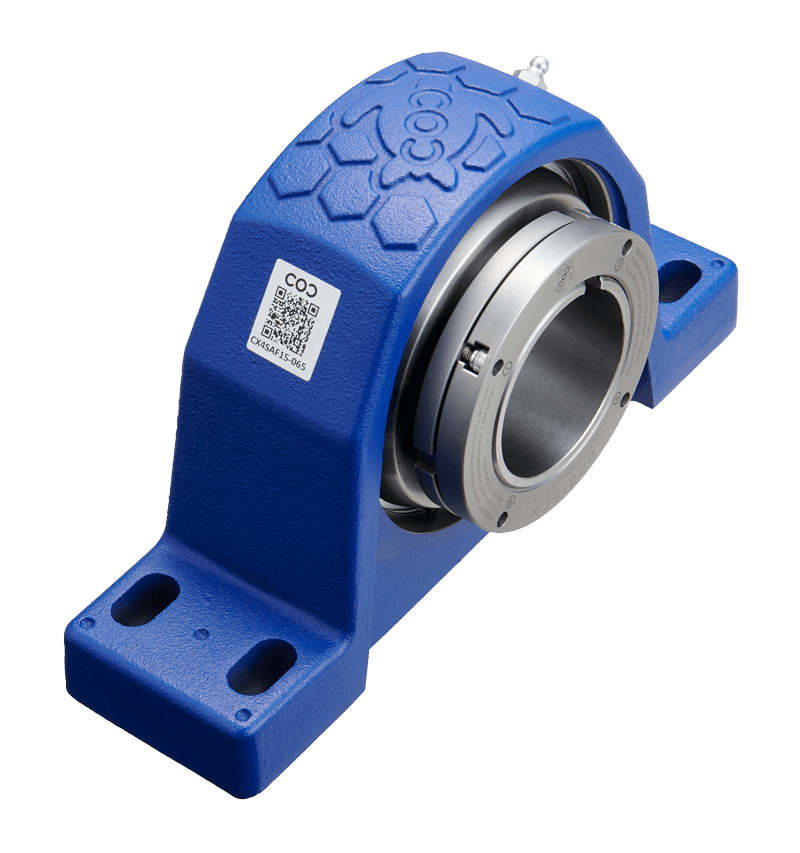

Unitized SAF version is added on the lineup. CROSSLOC™ inserts with one piece SAF dimension housings. This is compatible with standard SAF split plummer block units. It is shaft ready, factory assembled and fully lubricated. It can be mounted six times faster than standard SAF plummer blocks. Two bolt and four bolt pillow block are available.

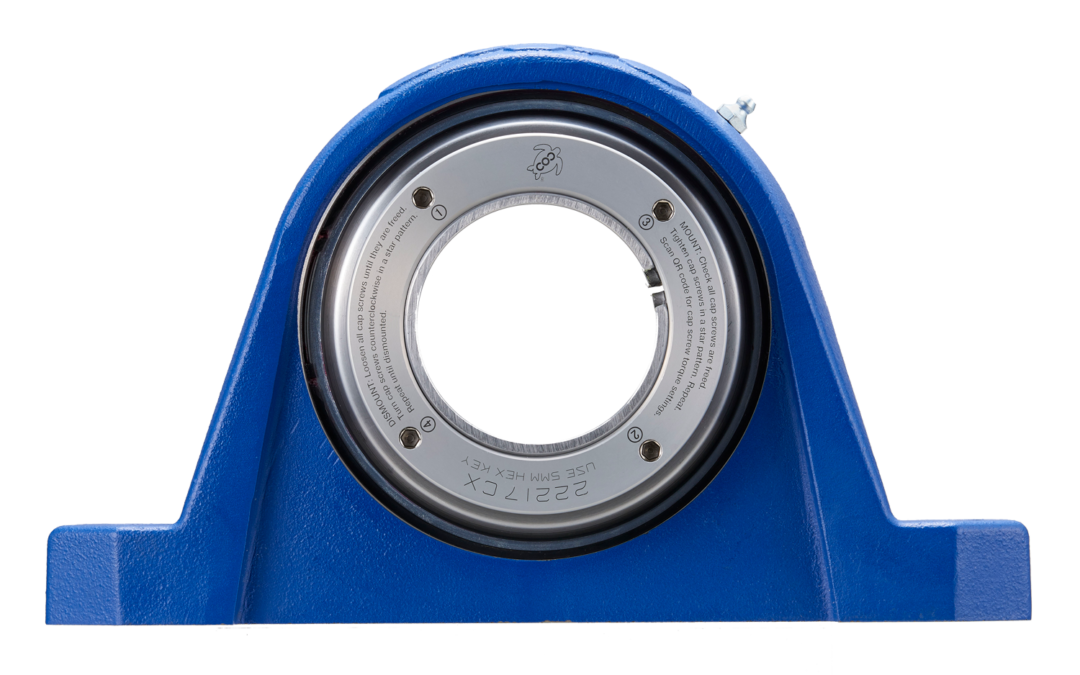

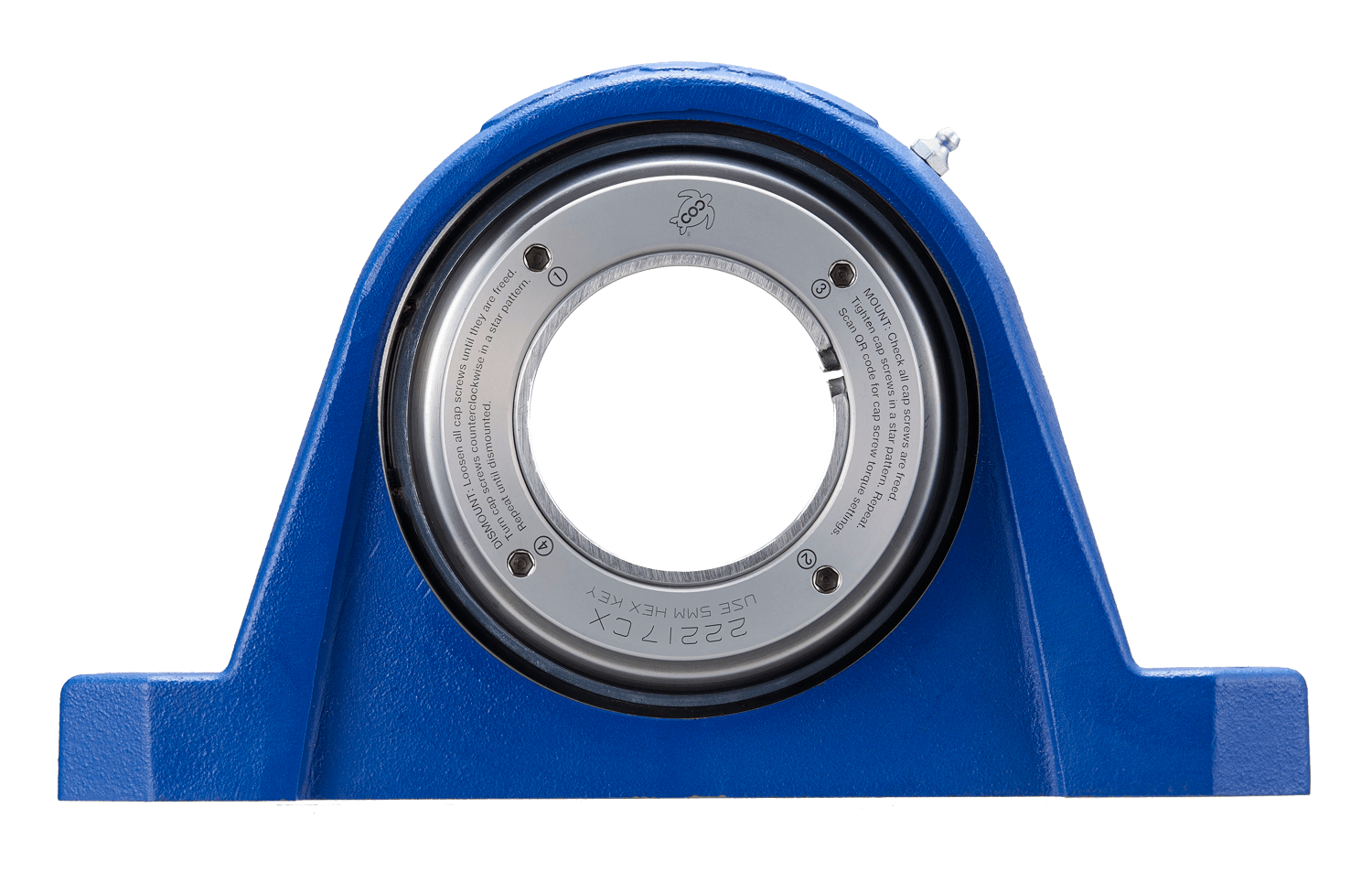

Laser marked instruction of CROSSLOC™

We are planning to add laser-marked instructions for CROSSLOC™ on the nut. CROSSLOC™ is very user-friendly, requiring only the tightening of cap screws to lock and loosening them to unlock. However, we aim to enhance users’ understanding of this system to prevent potential failures and ensure safety on-site. These instructions will be provided in several languages through QR codes scanned from the housing’s pages.

<Information for your technical support team>

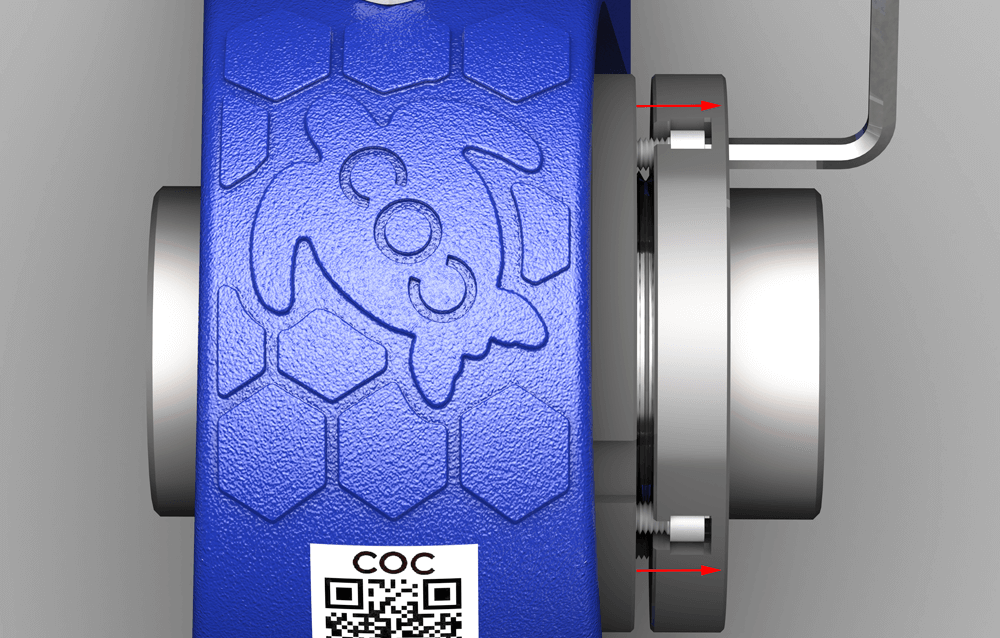

This locking system consists of two nuts: the inside nut connects with the inner ring, and the outside nut connects with the adapter sleeve. These two nuts are secured using four (or six) cap screws. The outside nut, attached to the adapter sleeve, is manipulated by the cap screws for locking and unlocking. To lock, the adapter sleeve must be pulled, and left-hand cap screws should be turned clockwise to pull and counterclockwise to push. Tightening the cap screws increases the gap between the two nuts, causing the adapter sleeve to move outward. Loosening the cap screws reduces the gap, moving the adapter sleeve inward. To prevent cap screws from twisting or getting damaged, the outside nut should move in parallel with the inside nut. Therefore, it is essential to tighten the cap screws in a star pattern and repeat the process. You may need to repeat this several times to ensure all cap screws are perfectly tightened, similar to the procedure for tightening automobile wheels.

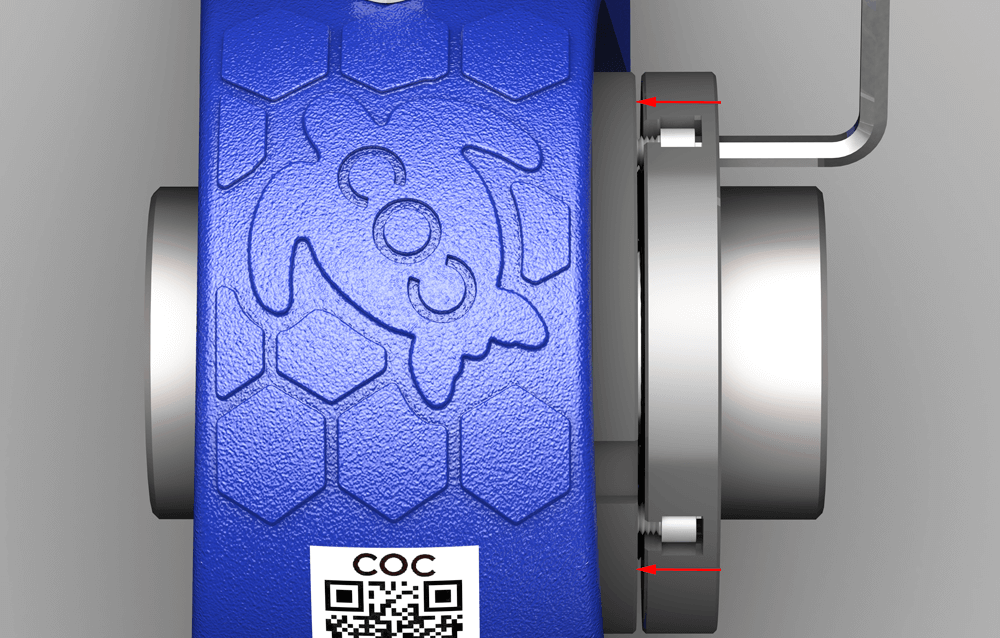

When you want to unlock CROSSLOC™, you’ll need to loosen and turn counterclockwise. Although it involves a leftward rotation, turning counterclockwise will not loosen it. Begin by loosening all cap screws to free the components. Next, push the outside nut to release the adapter sleeve from the inner ring. Turn the cap screws counterclockwise in a star pattern and repeat until disassembled. The procedure for unlocking is the same as for locking, with the outside nut moving in parallel.

LOCK

UNLOCK

The outside nut should move parallel to the inside nut.