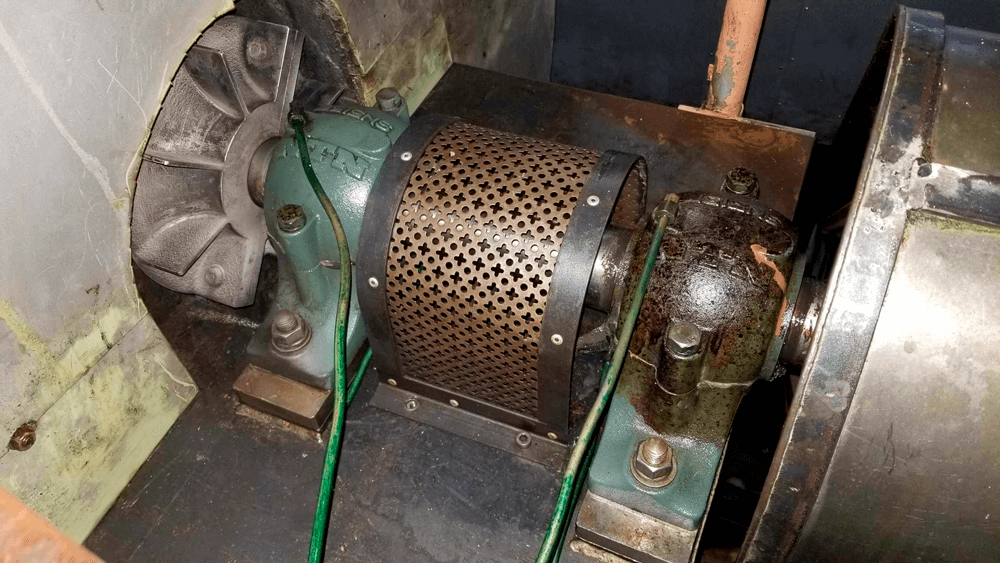

Case Study : CX2SN15-065L

Steam Blowers of the textile manufacturer (1900RPM)

BEFORE

SN515

The surface temperature of the unit rises to 100°C (230° F) within two months of installation. The grease from the unit is changed every two months. The temperature decreases initially after greasing to 80°C (176°F) before starting to rise again.

They cannot change all the grease using a grease gun so they have to take apart the upper part of the housing and clean out all the old grease by hand. This process takes over two hours.

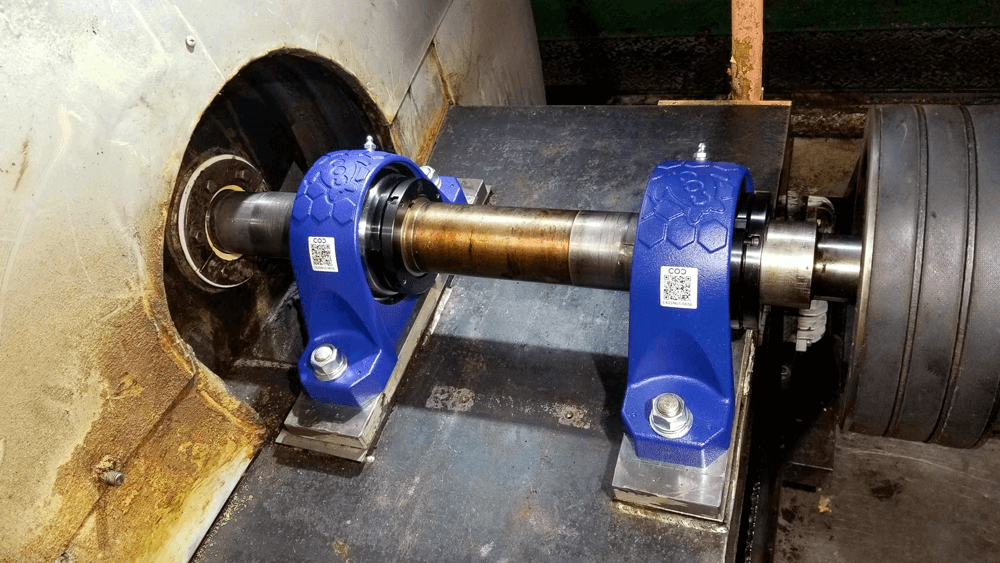

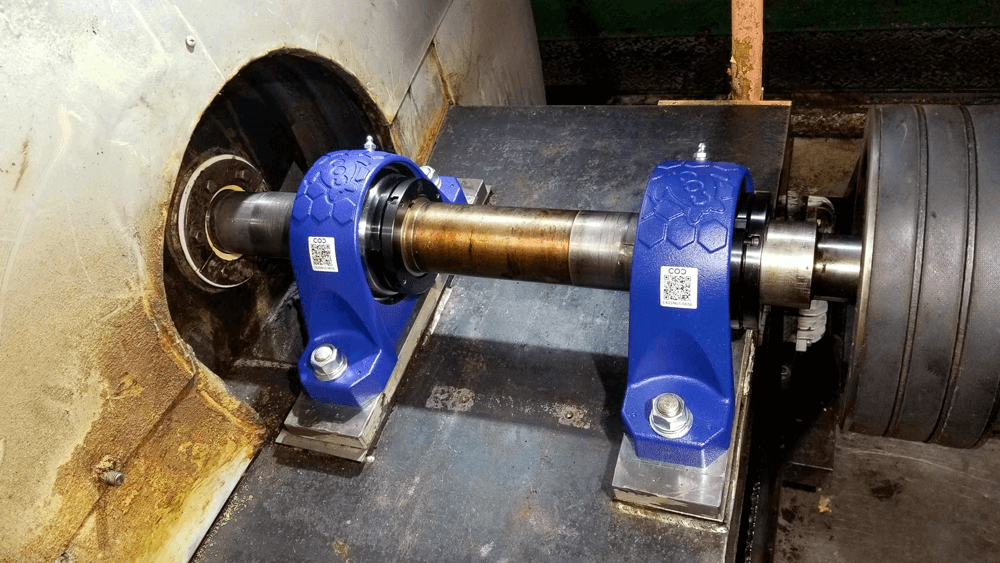

AFTER

CX2SN15-065L

The surface temperature of the units initially went up to 120°C (248°F) and then decreased to 80°C (176° F) after the excess grease was purged within 24 hours. The temperature since then has remained between 65°C (149°F) and 80°C (176°F).

They don’t need to worry about the temperature any more. The COC unit saves money in downtime, labor and the cost of the grease.

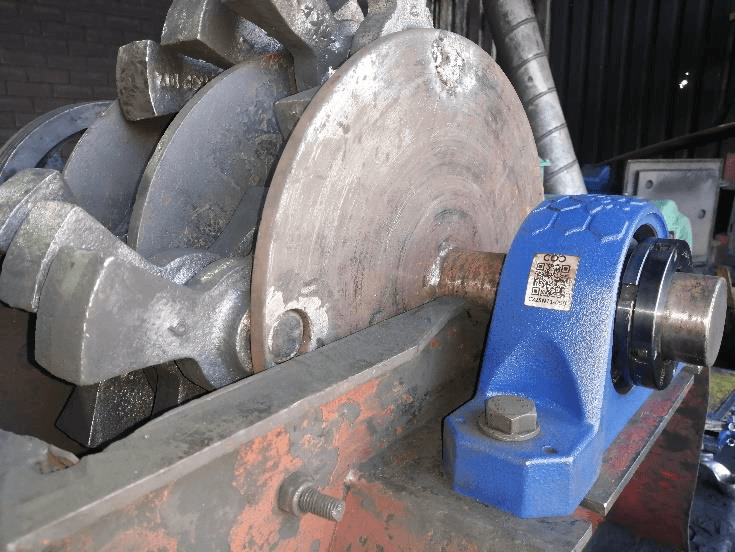

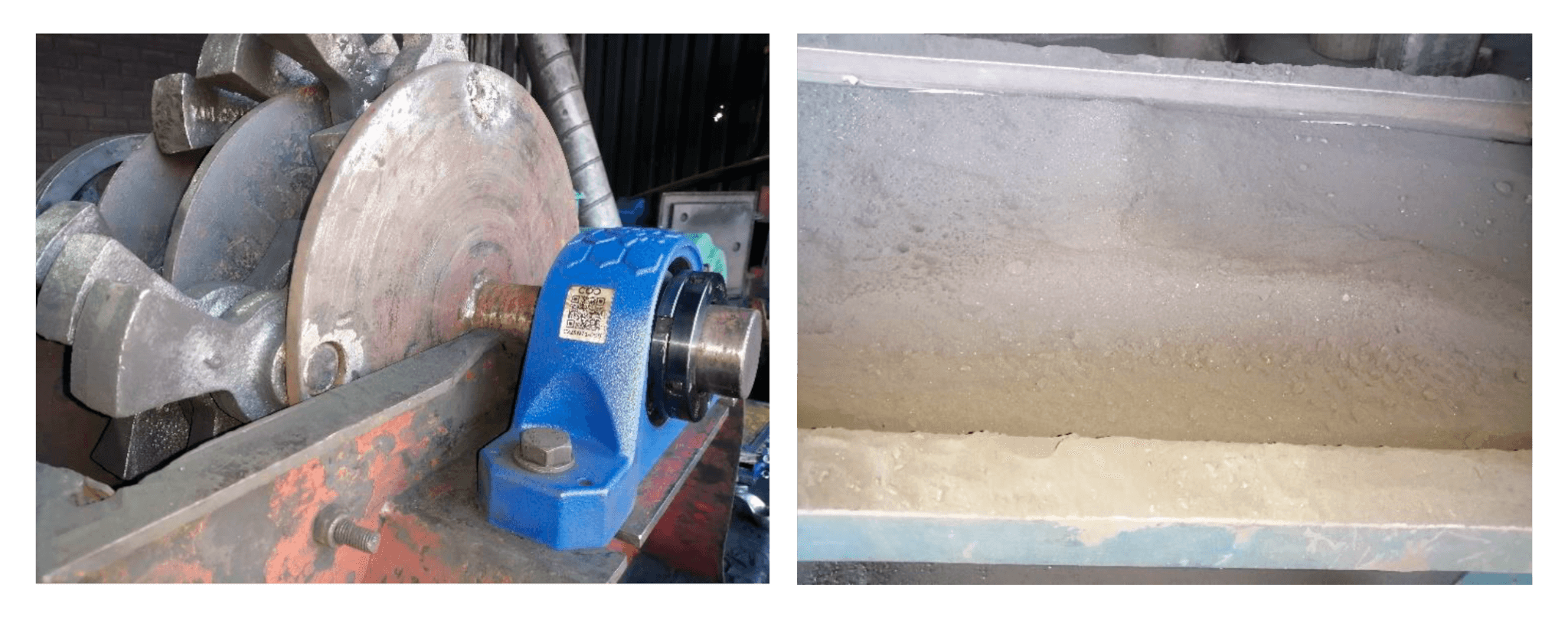

Feedback from South Africa

This Coal Pulverizing Hammer Mill application exposes the bearing to extreme dusty and vibratory conditions and the 22211 E1 KC3 spherical roller bearings in a standard SNK511 plummer block were lasting between 4 to 8 weeks. The bearings were failing due to the ingress of coal dust in the bearings.

Our two CX2SN11-050 bearings ran perfectly from the 1st of October 2020 to 7th of June 2021. The COC bearing lasted 8 months with easy installation and removal versus 1.5 months of operation with difficult installation and removal.

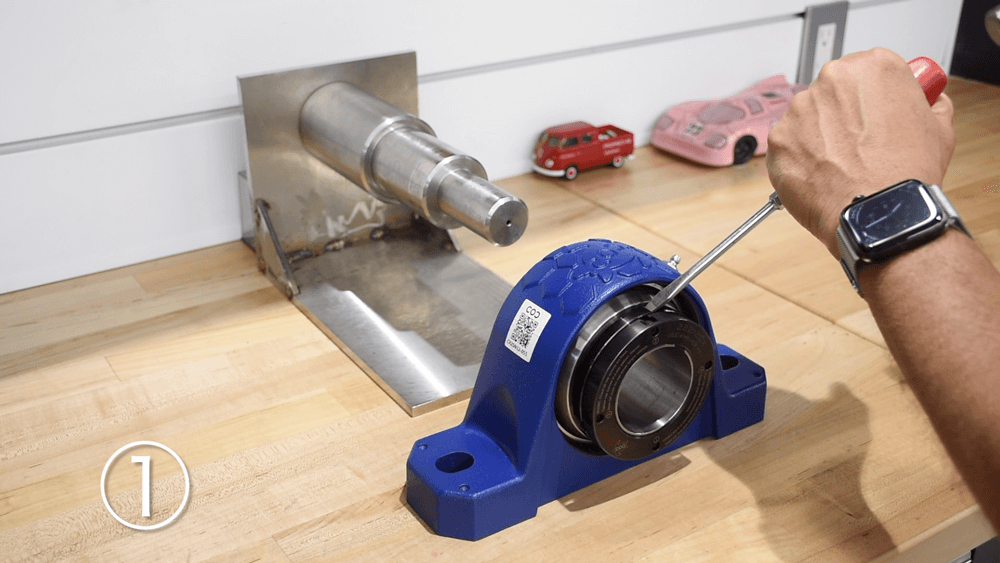

CX2SN product page updates

The individual product pages in the chart of CX2SN have been updated at https://www.crossocean.com/cx2sn/

The updates are noted below.

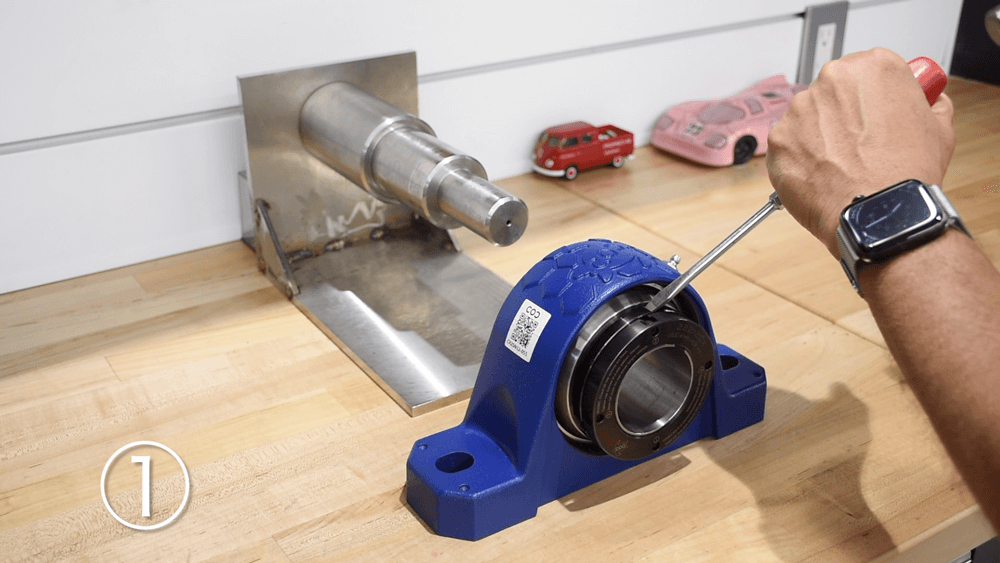

1. Notes on how to mount and dismount of CROSSLOC™.

2. How to make the bore smaller when the shaft is smaller than recommended shaft tolerance. (video)

3. Seal Speed Limits (rpm).

Scanned pages of the QR codes for the 2SN housings available in several languages for metric sizes.

CX2SN20-090L FOLLOW-UP

We wanted to post a follow up from our post from July 1st 2020. The company had switched from two piece plummer block unit SN520 to our CX2SN20-090L in July of last year. The COC bearing solved an issue that had been having for many years.

They called to thank us for our bearings because they used to have to change the SN520 every 3 months but our bearings are still running after 9 months.

They had ordered spare bearings to put on when the first set wore out but have had no chance to use them. Our COC bearings have saved them down time on the lines and the labor involved in changing the units out. They are so happy with the money they have saved by switching to COC. COC is so glad we have been able to solve this problem they had been having for so many years. These bearings are used outside by the ocean and we have told them that our covers would add even more protection is this environment.

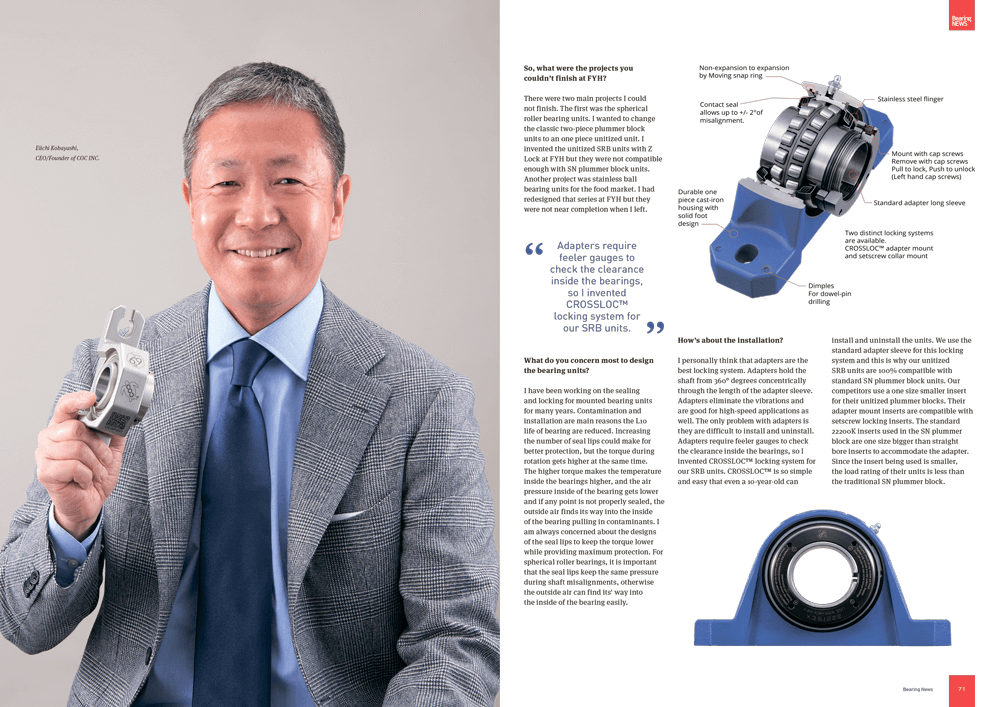

Bearing News Magazine Interview

Eiichi Kobayashi’s interview is on Bearing News Magazine March issue page 66.

https://issuu.com/bearingnews/docs/bearingnews2021-march-web/66

https://www.bearing-news.com/interview-a-tradition-of-innovation-for-mounted-bearing-units/