A success story with COC

Here is an article from our partner in South Africa.

Longer life and reduced downtime are the cornerstones of our products.

We are certain this customer will agree.

Here is an article from our partner in South Africa.

Longer life and reduced downtime are the cornerstones of our products.

We are certain this customer will agree.

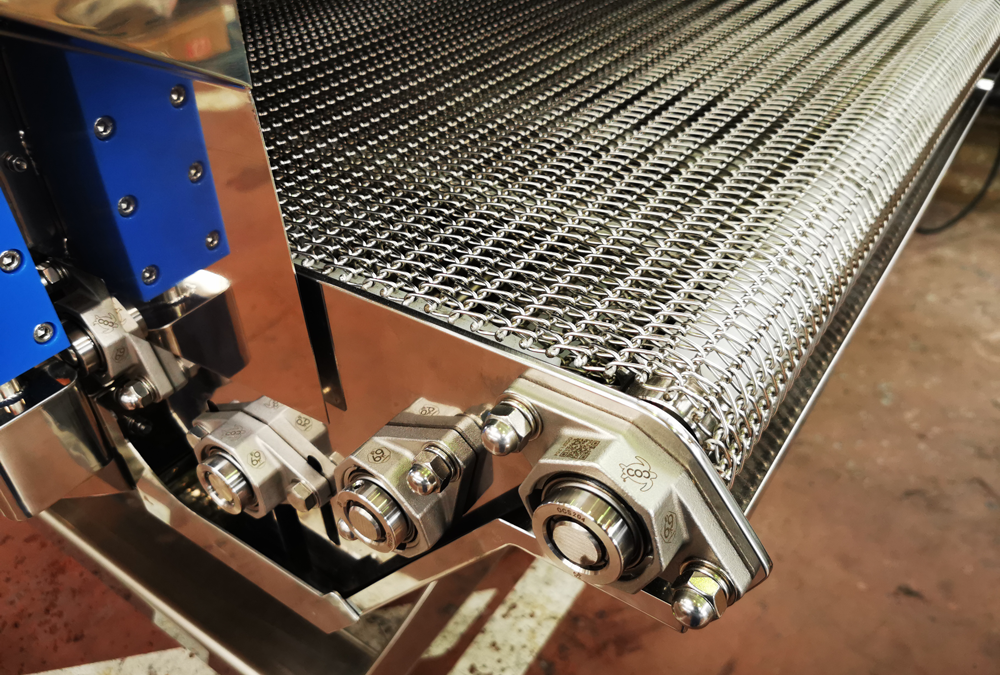

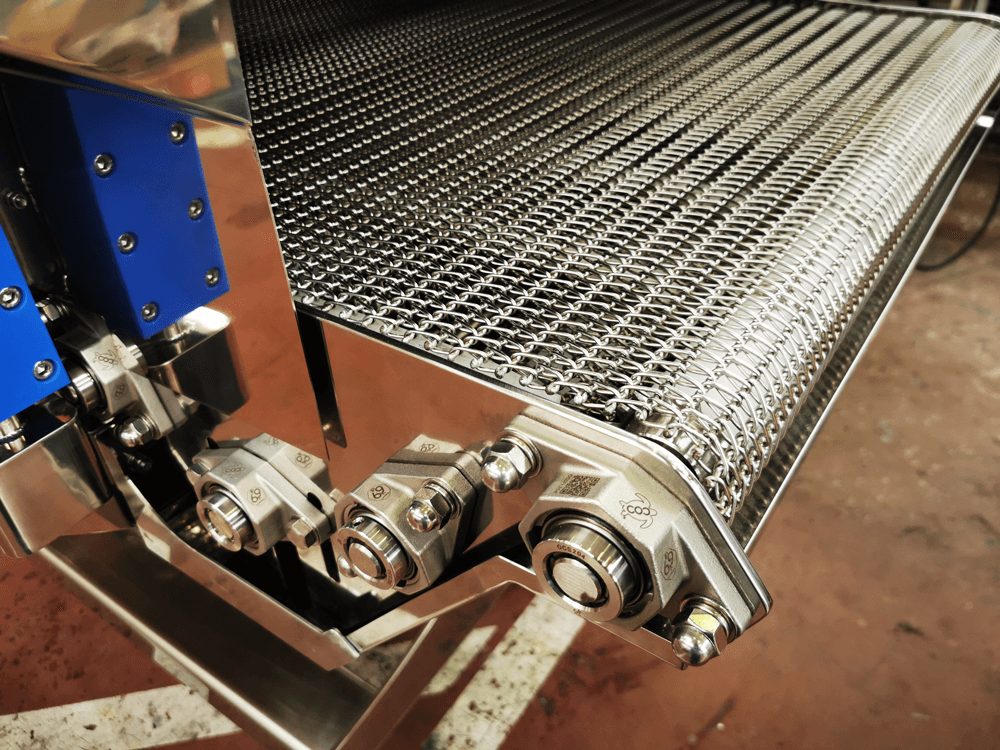

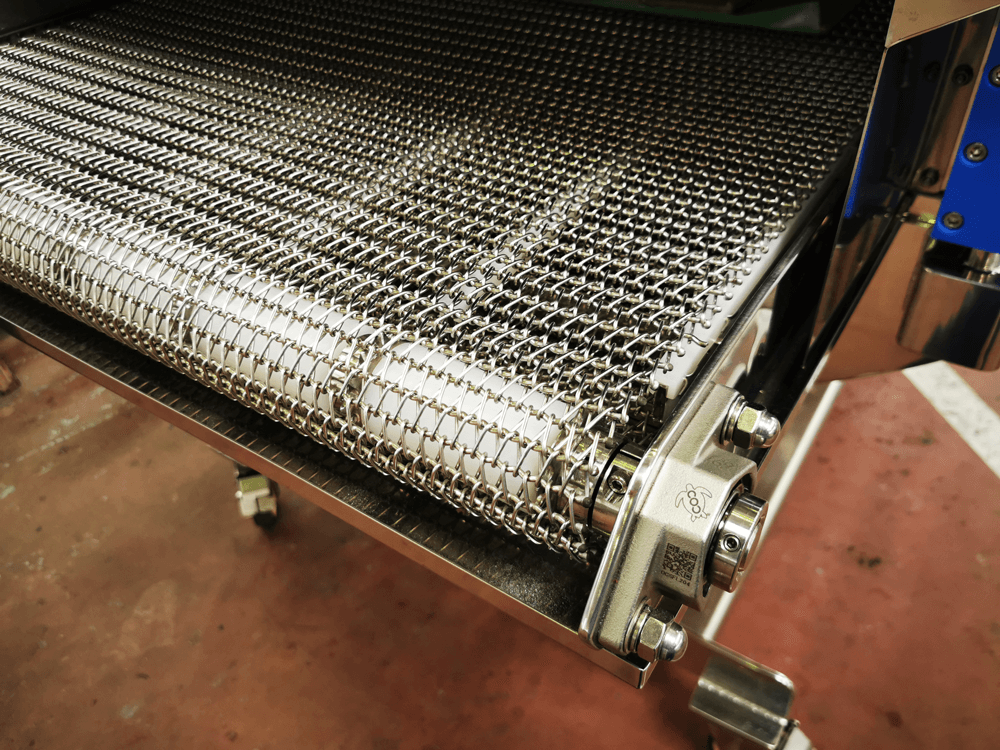

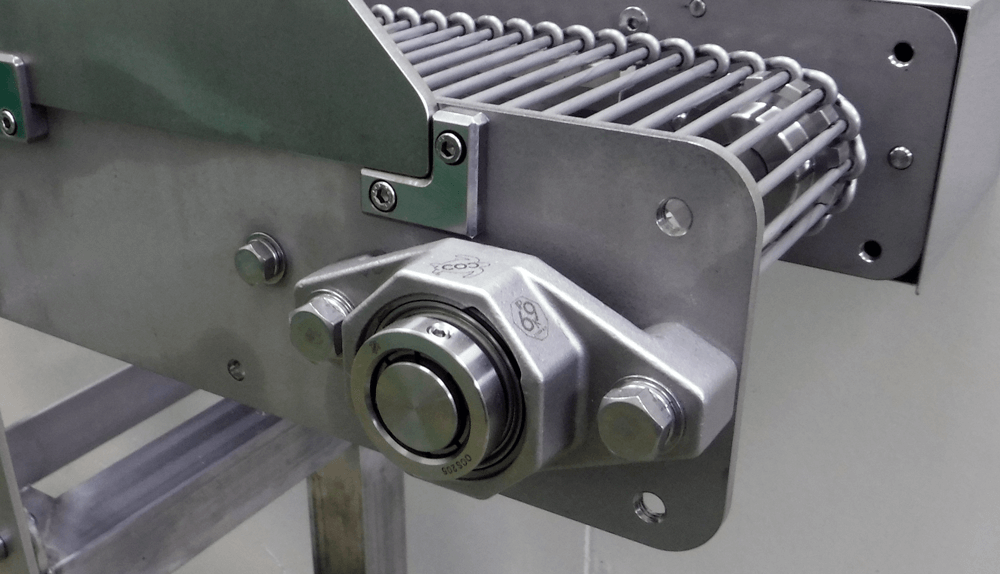

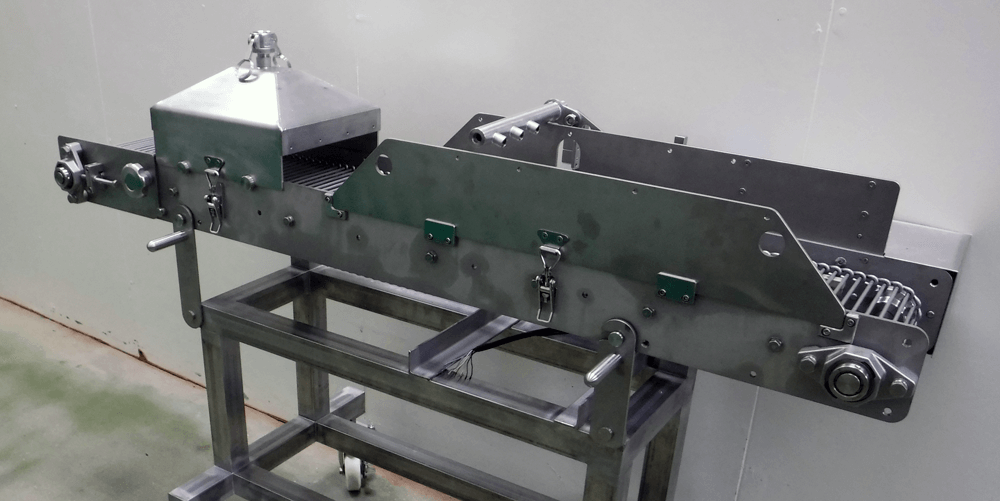

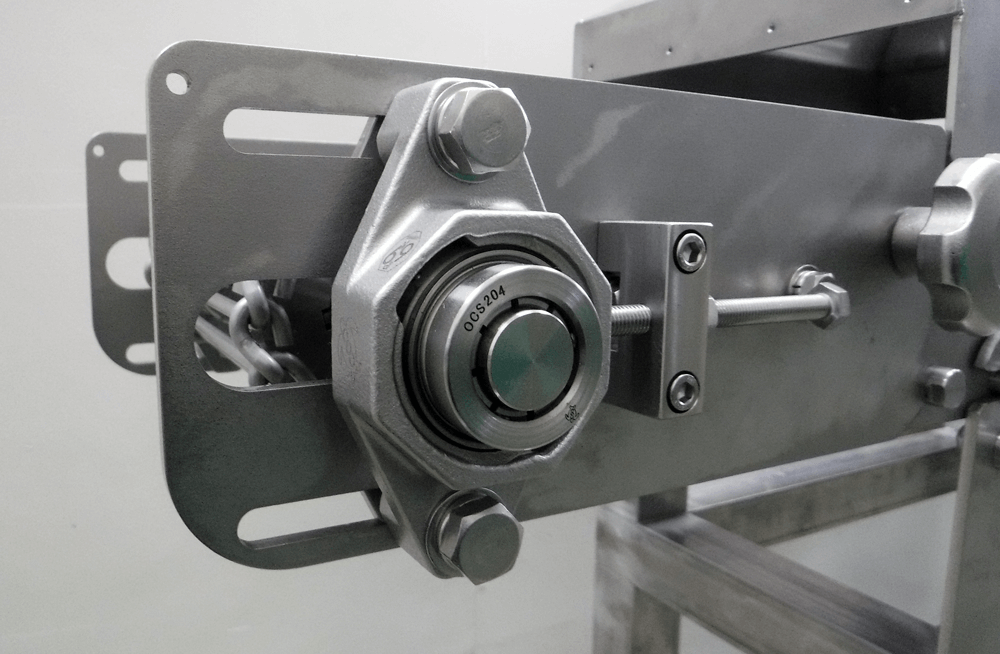

Saniline OCSFL204 were installed in the new released conveyor steamer which was introduced in FOOMA JAPAN 2022.

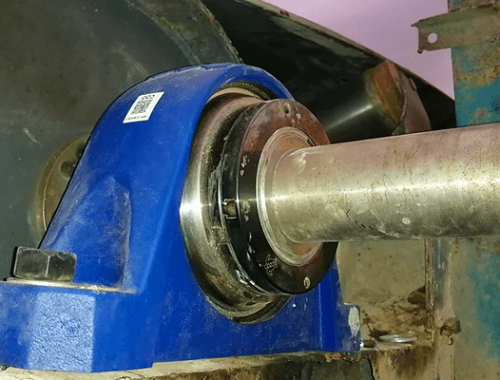

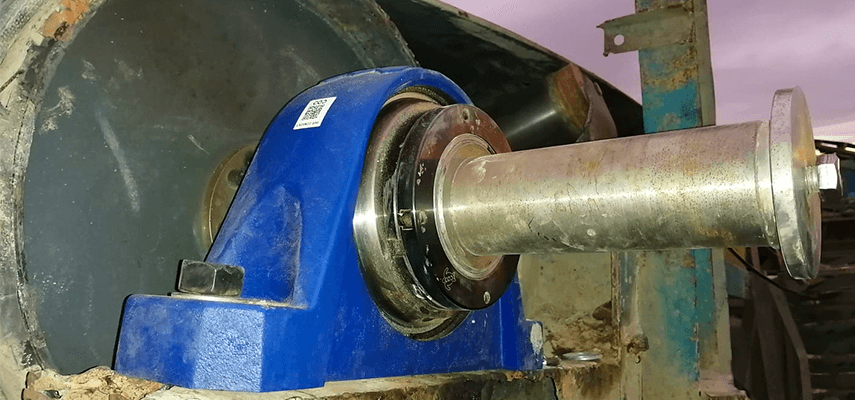

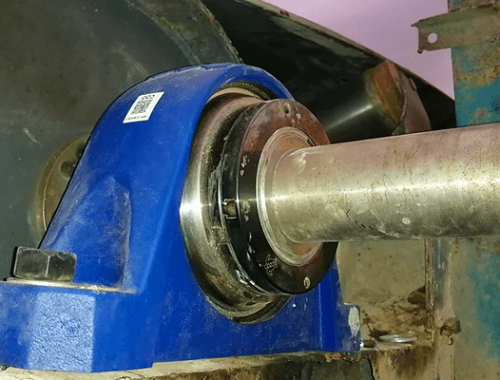

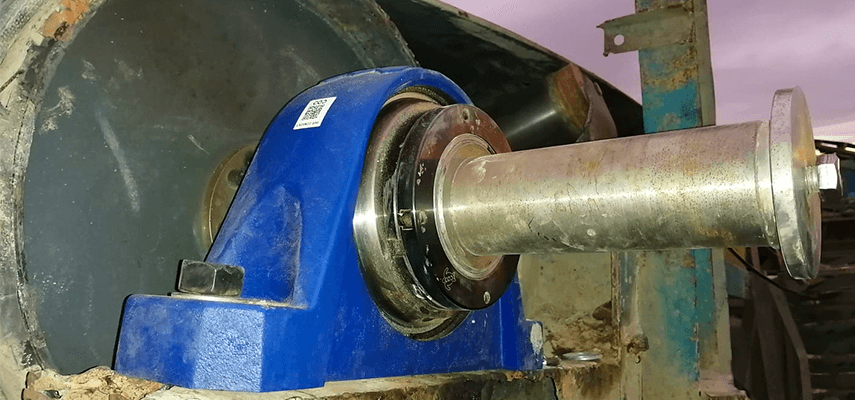

OCSHFL204 stand off units are installed in new Tuna processing conveyors.

Industrial Motion Events is an all-year networking event, connecting PT/MC community buyers & suppliers from six different industries from 21 March till 7 December 2022.

Please visit our booth.

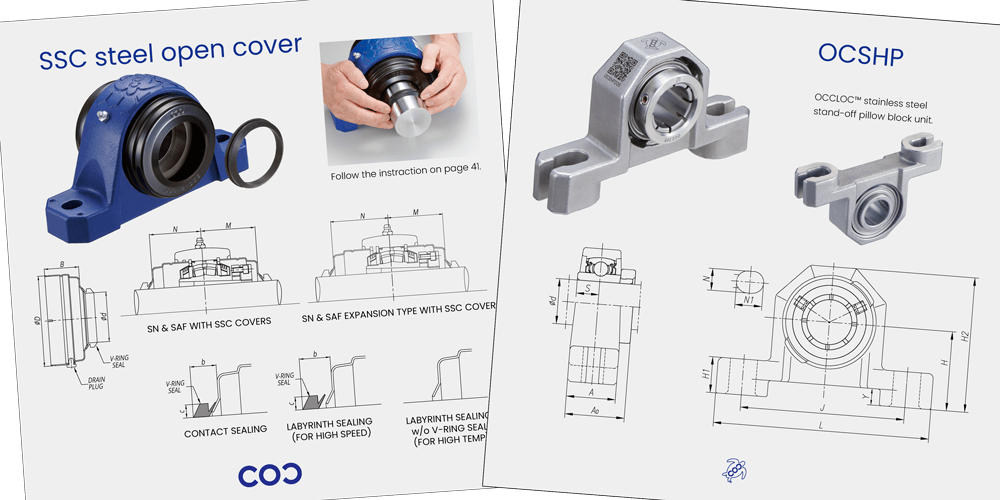

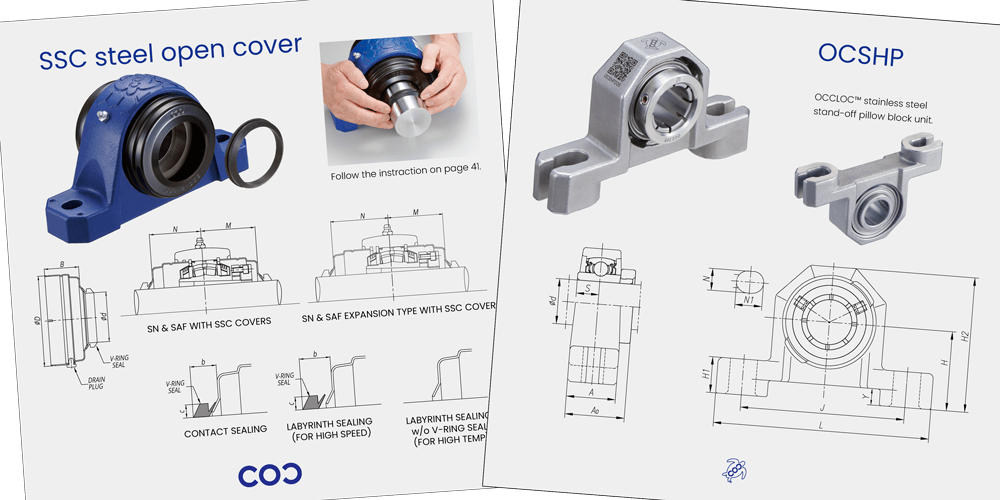

Both SRB and Saniline PDF catalogs were updated. New SSC open covers in SRB and the pictures of bottom and backside of Saniline have been added.

https://www.crossocean.com/srb-catalog/

https://www.crossocean.com/saniline-catalog/

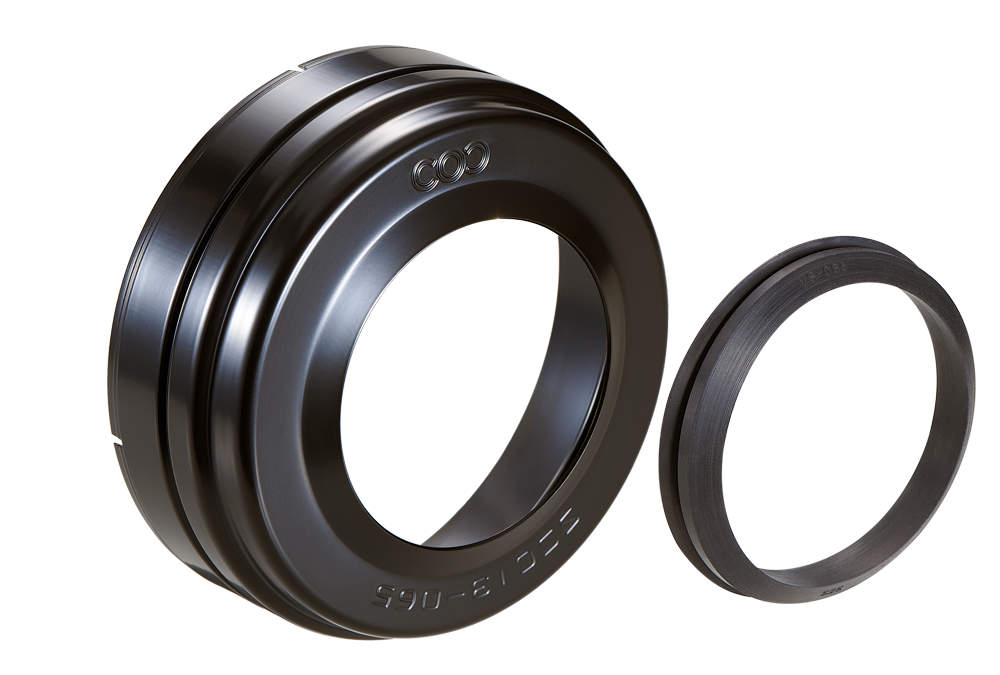

CX2SN13-60 WITH SSC13-60

CS2P13-65 WITH SSC13-65

Each one size of SSD closed end covers are for all units. However, SSC open covers have different bore sizes for CX (SN & SAF) units from CS & CXC units. CX inserts are one size bigger than CS & CXC inserts to accomodate with the standard adapter sleeves. Please check in detail at https://www.crossocean.com/ssc-covers/

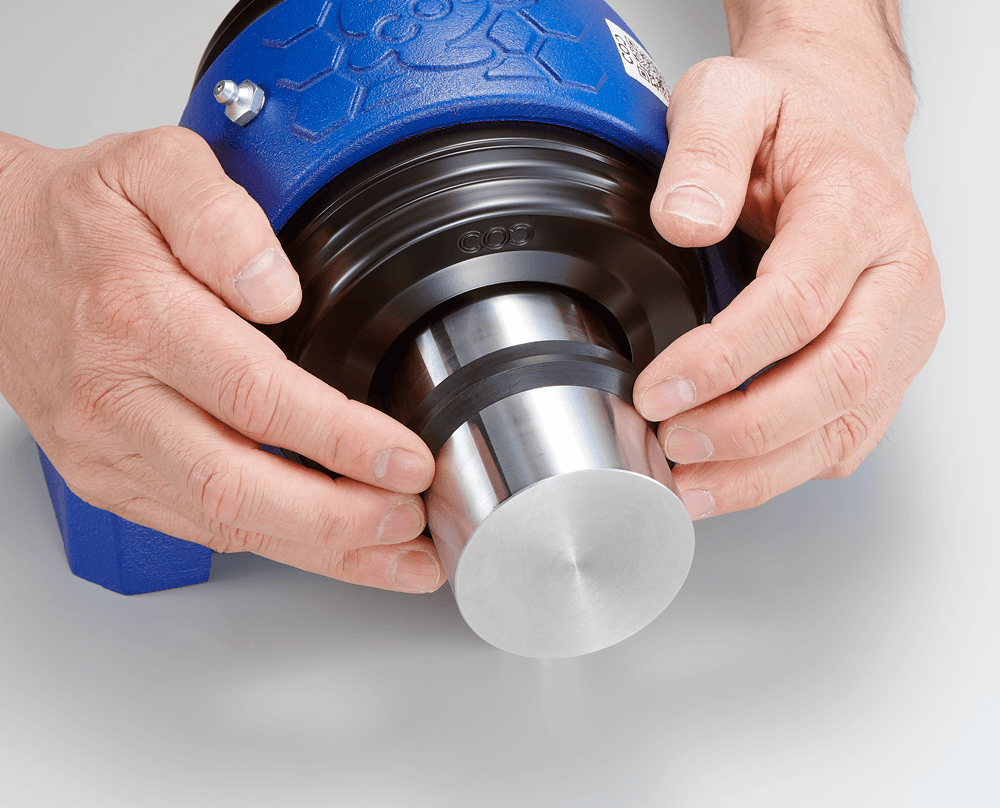

Installing SSC covers is very simple.

1. Make sure that the shaft is dry and free from grease or oil.

2. Lubricate the lip of the V-ring with a thin film of grease or silicone oil.

3. Slide V-ring along the shaft by applying pressure and rotating shaft by hand.

CONTACT SEAL

LABYRINTH SEAL

(HIGH SPEED)

W/O V-RING SEAL

(HIGH TEMP)