B7

The grease fittings, located on both sides of the housing known as B7, are now available. We have occasionally received requests for an additional tapped hole for the smart sensor, and B7 can accommodate that.

The grease fittings, located on both sides of the housing known as B7, are now available. We have occasionally received requests for an additional tapped hole for the smart sensor, and B7 can accommodate that.

This is the follow-up from our post from March 31st 2021.

Our bearings have been running smoothly for three years, whereas our competitors typically experience failures within just three months.

They have only performed one maintenance task in the last three years, which is lubricating the bearings once a week.

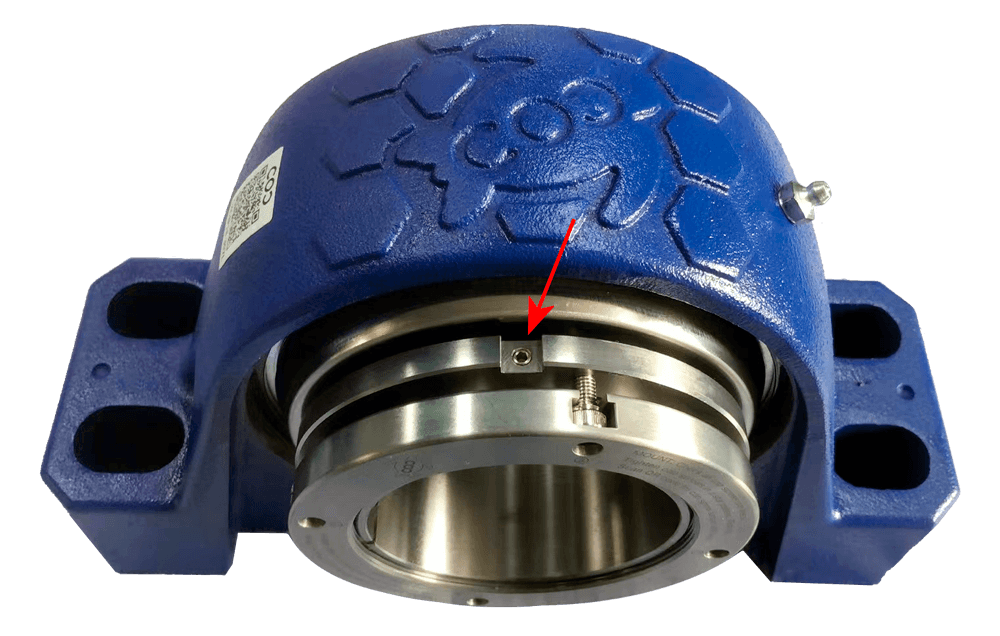

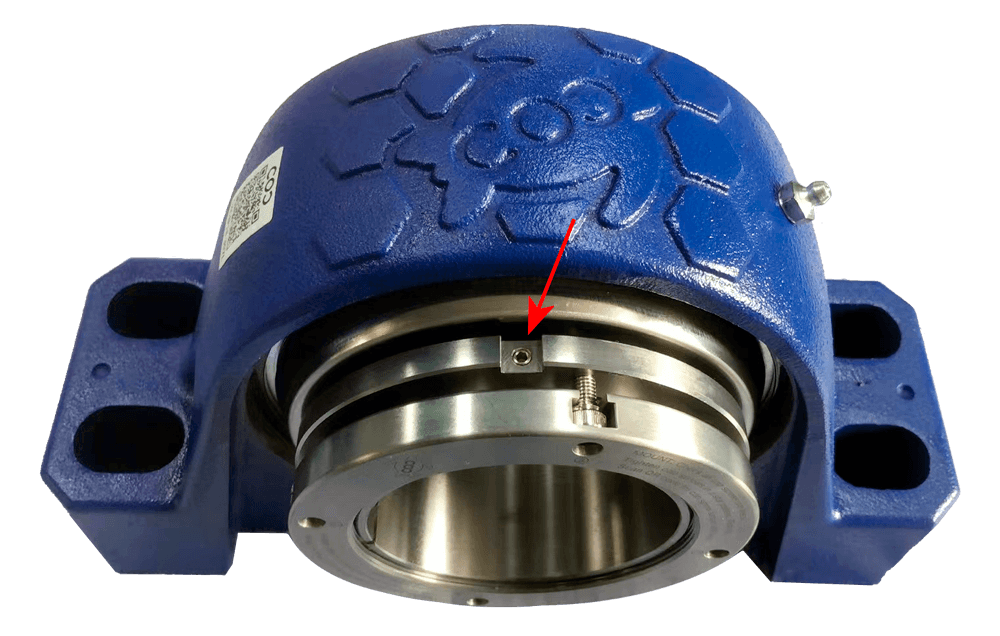

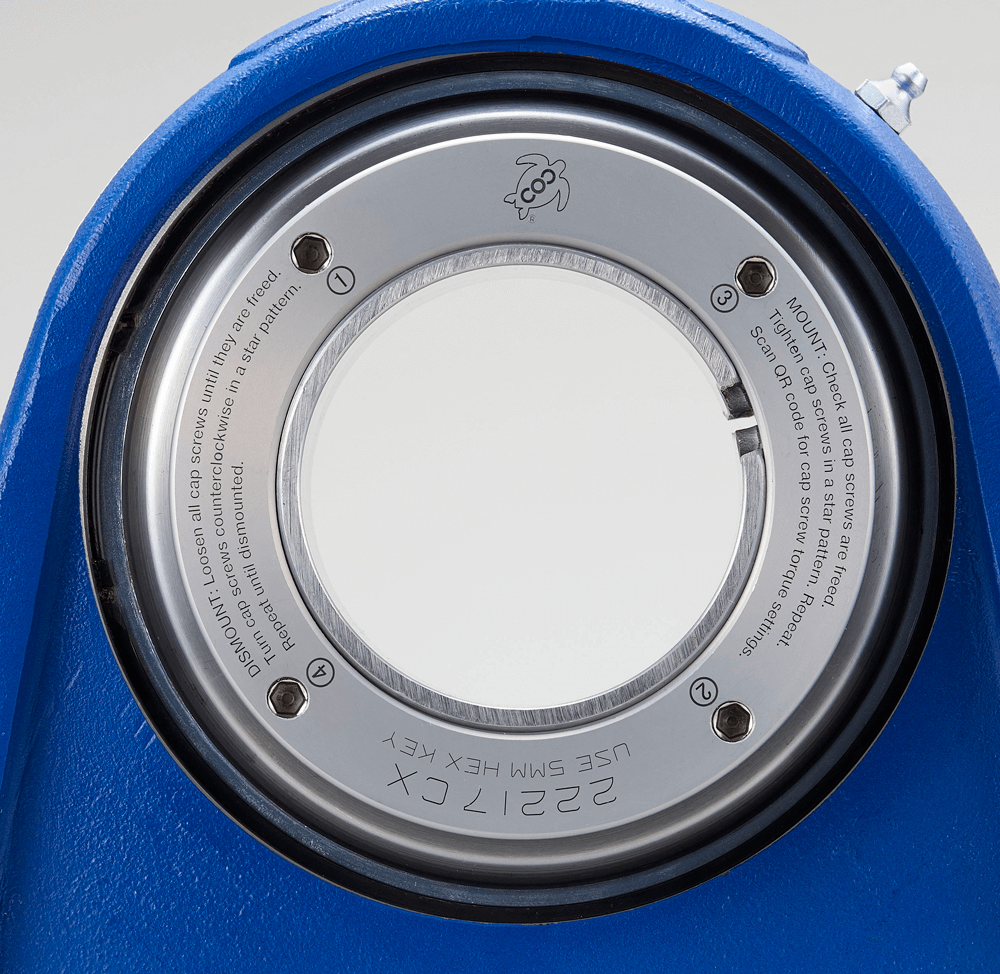

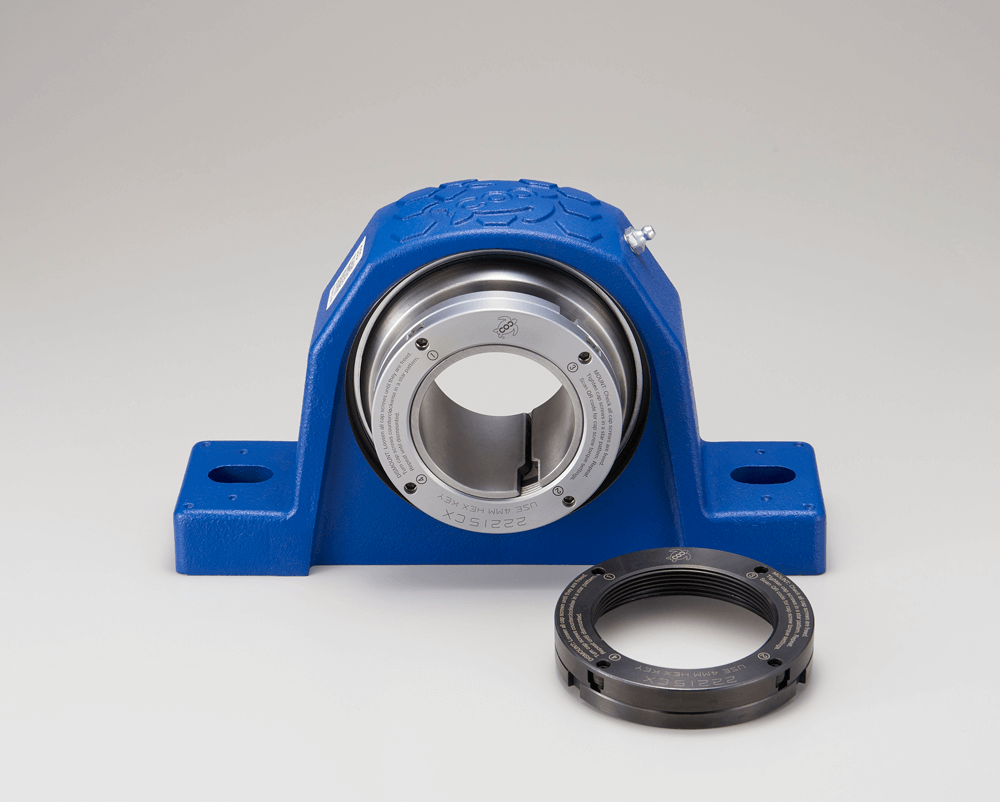

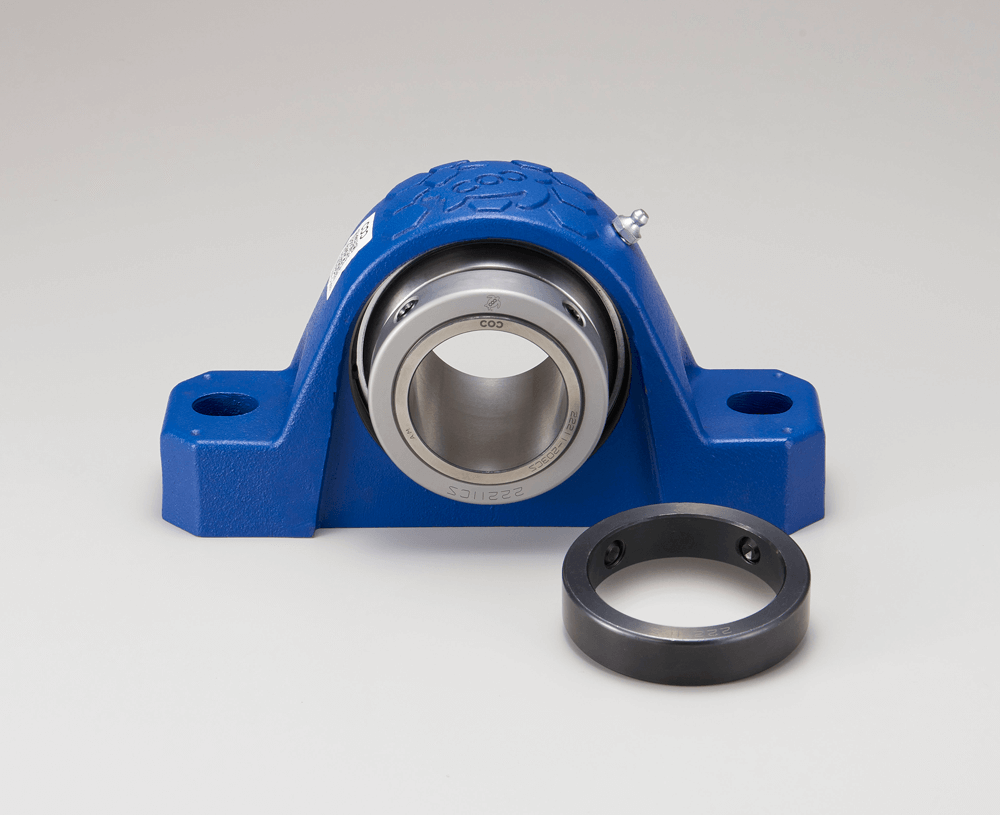

We have added a setscrew lock to the inside nut of all CROSSLOC CXC units.

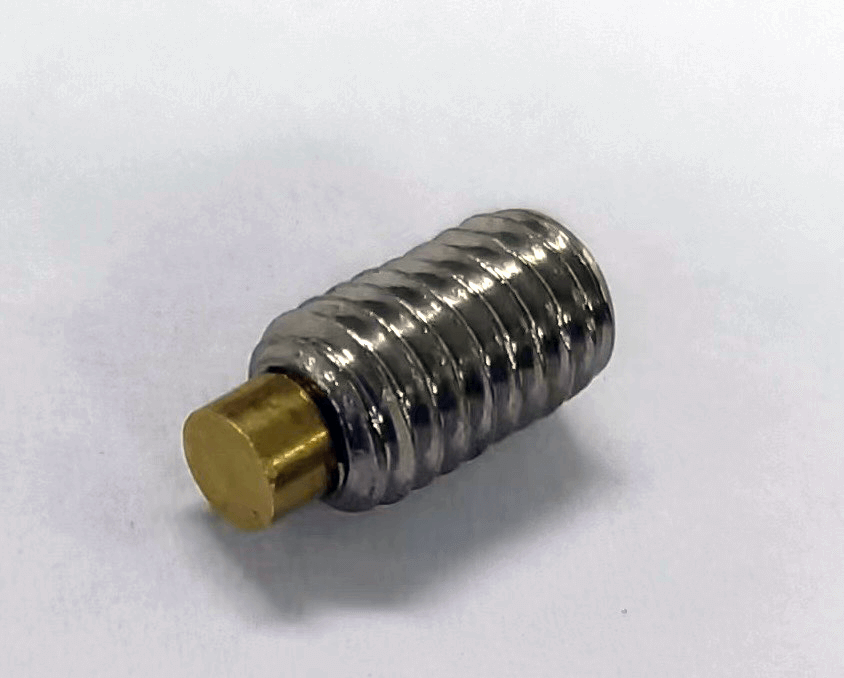

When the shaft rotates rapidly counterclockwise and reaches high speeds, heavy, large nuts increase the risk of the CROSSLOC CXC nuts coming loose and pulling the sleeve. To enhance safety, we have added a setscrew to secure the nut in place. The setscrew features a brass tip to prevent damage to the threads.

The sleeve of the CROSSLOC CX is designed to be pull-to-lock and does not require this additional locking mechanism.

We have been receiving questions about our SRB and Saniline from customers as below.

What is the difference between CX and CXC?

I disassembled CROSSLOC. What is the gap between the nuts to reset?

Can I use underwater?

Do stainless steel bearings rust?

We have FAQ pages for each series now. You can find the pages in the menu or the links below.

https://www.crossocean.com/srb-faq/

https://www.crossocean.com/saniline-faq/

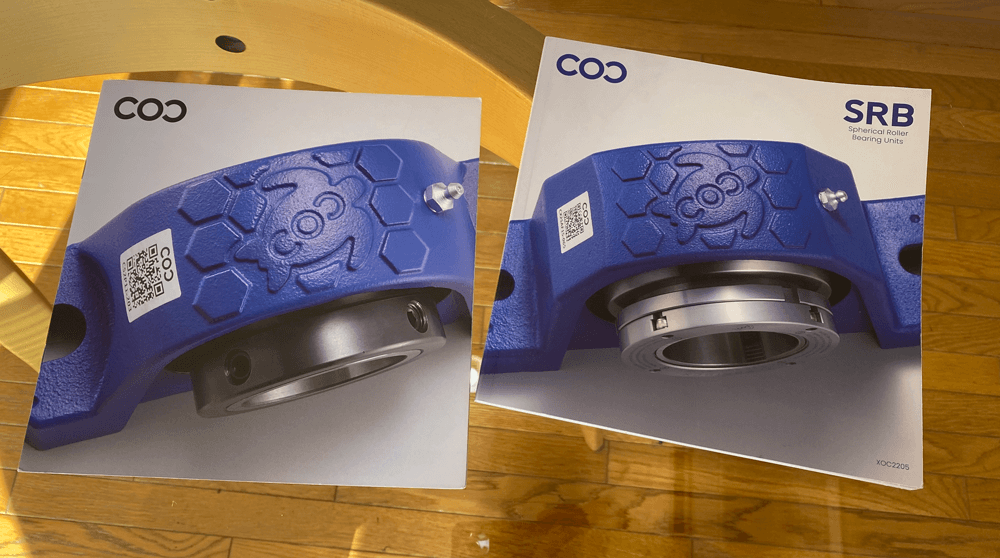

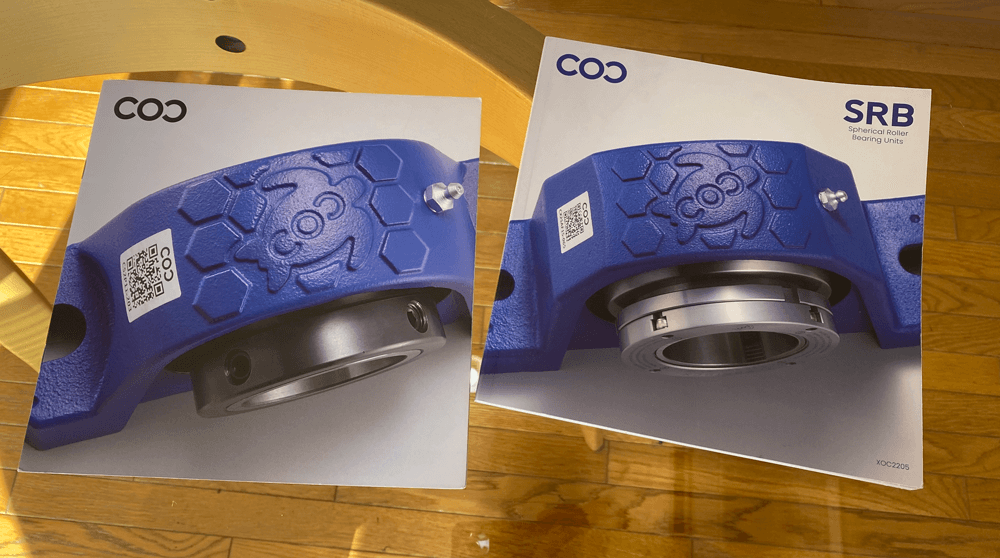

New SRB catalog

We are very excited to introduce our New Spherical Roller Bearing catalog!

Our first catalog pictured in the left, was released in August of 2019 with 26 pages. Since that time, we have been very busy adding valuable content and new products. Our catalog has now grown to 66 pages and includes more housing styles, more insert sizes and better interchange information. We are fortunate to have been successful over the past three years despite challenges faced during the pandemic and are thankful for our loyal customers. We hope you will find this new tool as valuable as we do.

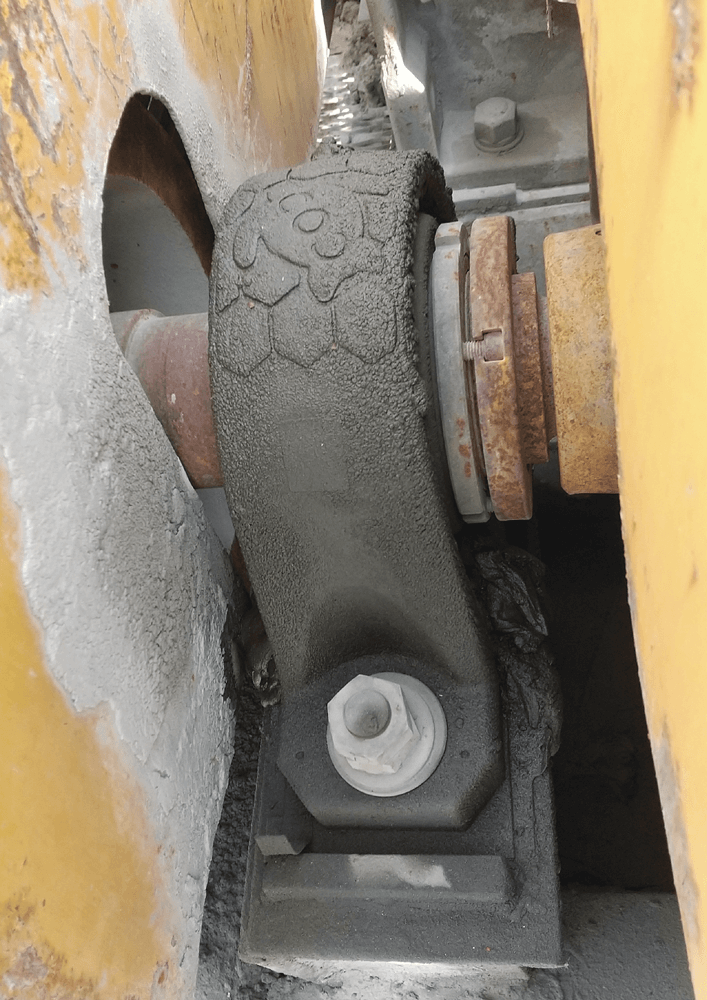

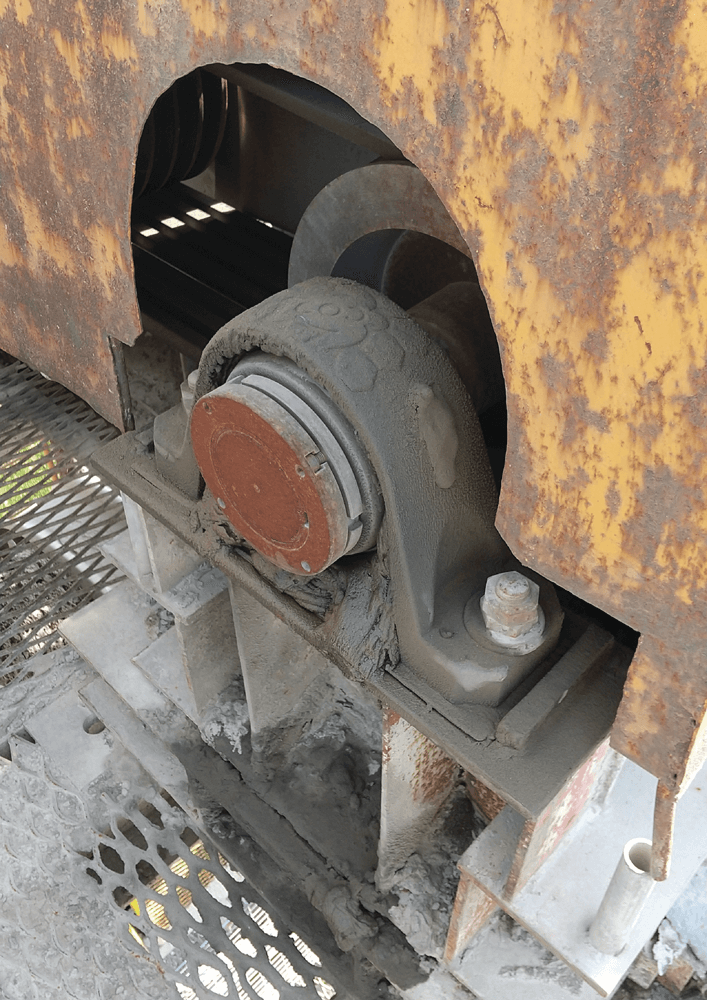

The following case study began July 1st 2020 and was featured on March 31st 2021 on our news page. The COC CX2SN20-090L has been running at 1480 rpm for over 2 years now.

Previously they had to change a traditional SN500 plummer blocks every 3 months and our bearing has now lasted 26 months! The customer has saved over 8 times the cost of the bearings not to mention all the saved down time to uninstall and reinstall regular SN500 units.

They say the bearings aren’t as beautiful as the day they were installed but they are still running flawlessly and will continue to run with proper lubrication.

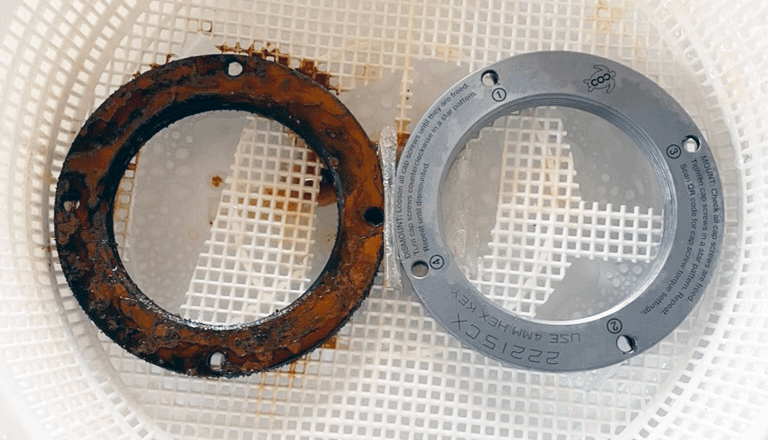

As you can see in the picture the black oxide coating on the CROSSLOC nuts is not doing anything to help protect against corrosion at all. This application is a landing conveyor near the coast where corrosion is a problem due to the salty atmosphere.

Black oxide coatings are very popular and they usually don’t have issues for most applications. Since our COC bearings last so long we don’t want our CROSSLOC nuts and cap screws to break making dismounting hard.

We are going to change from a black oxide coating to our new special coating which has great corrosion resistance in all applications. As you can see from the salt spray test results below it protects from corrosion a lot more effectively than a black oxide coating.

Our new coating will become the standard for both CROSSLOC nuts and CS set collars. All cap screws for CROSSLOC will be nickel plated. The timing will vary by the size of bearings and the stock on hand of existing parts.

Our goal at COC is to always be improving our already superior product line.