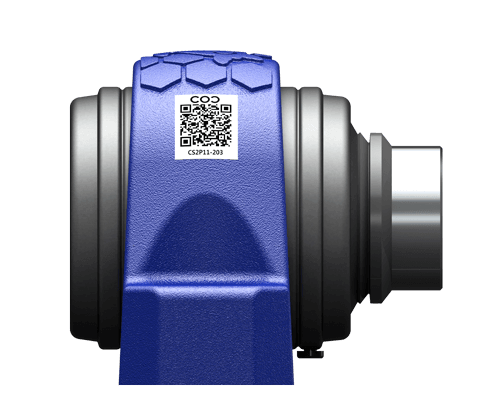

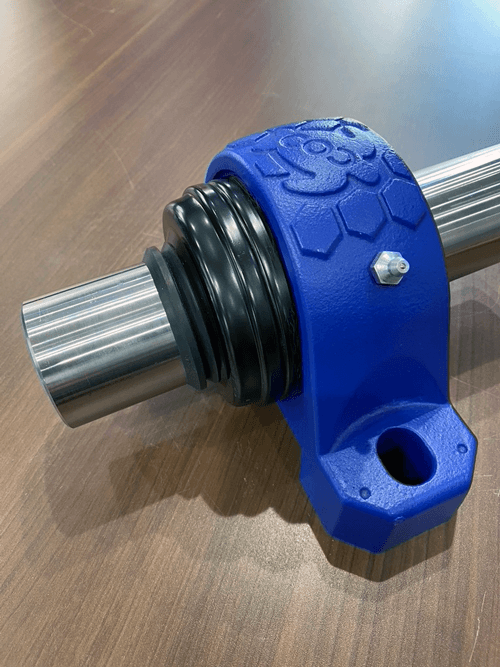

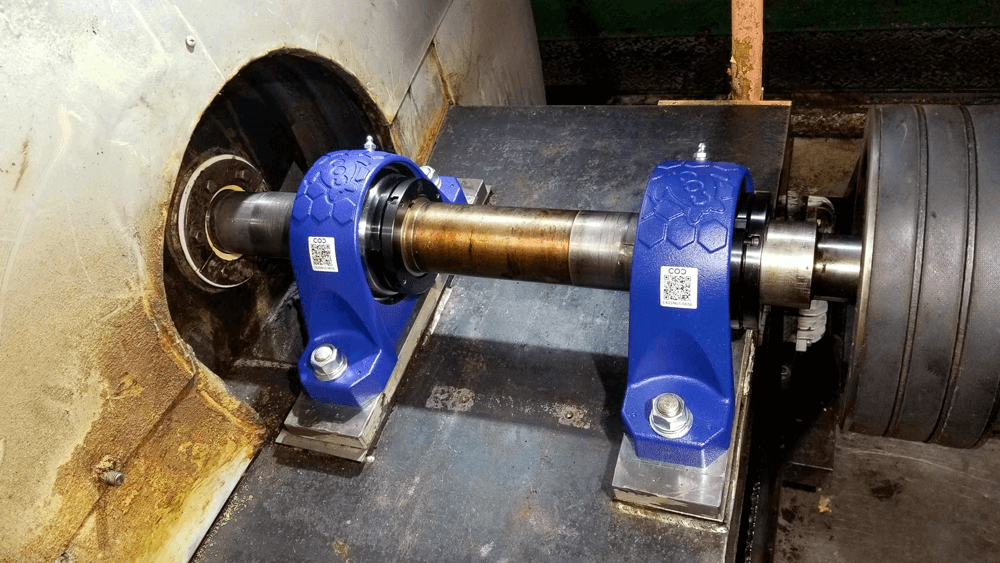

The demo machine of Turkish distributor

Our Turkish distributor built the demo machine.

That represents how our sealing performs very well.

Our Turkish distributor built the demo machine.

That represents how our sealing performs very well.

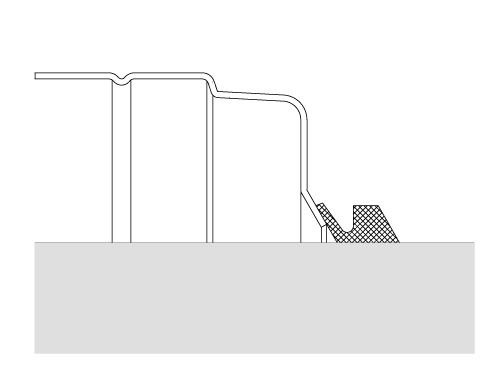

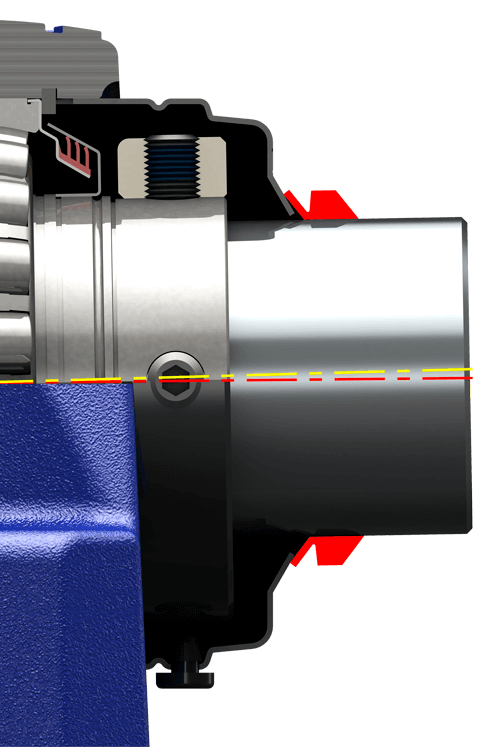

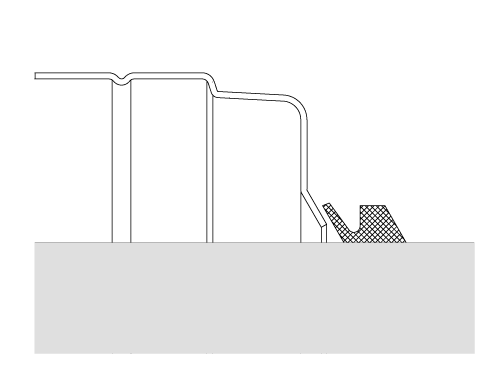

OPEN COVERS FOR SRB UNITS

Our bearings will last long and CROSSLOC™ nuts can rust sometimes by rain in outside applications.

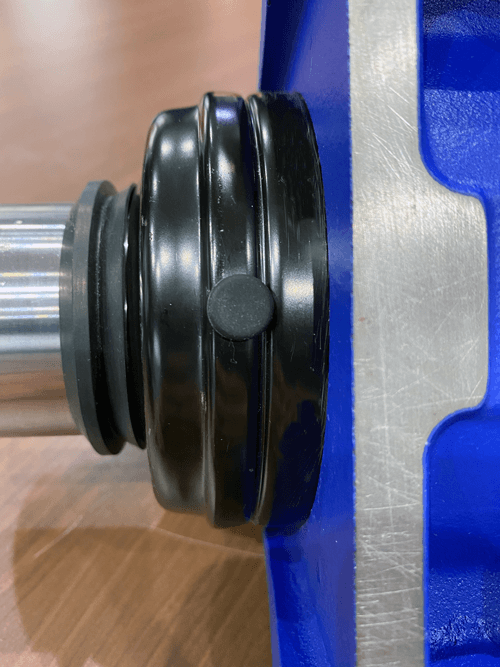

The new open steel cover with V-ring seal will protect from the dirt and water. This new open cover is being added to our existing end closed covers and will protect better for those applications.

The molded rubber V-ring seal is press-fit on the shaft and rotates with shaft. The seal lip contacts on the cover not the shaft, so the shaft doesn’t get any damage from the seal lip.

Due to the tapered seal contact area of the open cover, the seal lip maintains full contact even when misaligned.

When the Open cover is used with the bearing with labyrinth seals for high speed, make a space between the seal lip and open cover to keep it from contacting. The V-ring seal will be an extra barrier as a flinger.

The open cover has the plugged drain hole and you can take the plug out for the labyrinth seal applications to drain ingressed water.

New open covers will be available from March 2022.

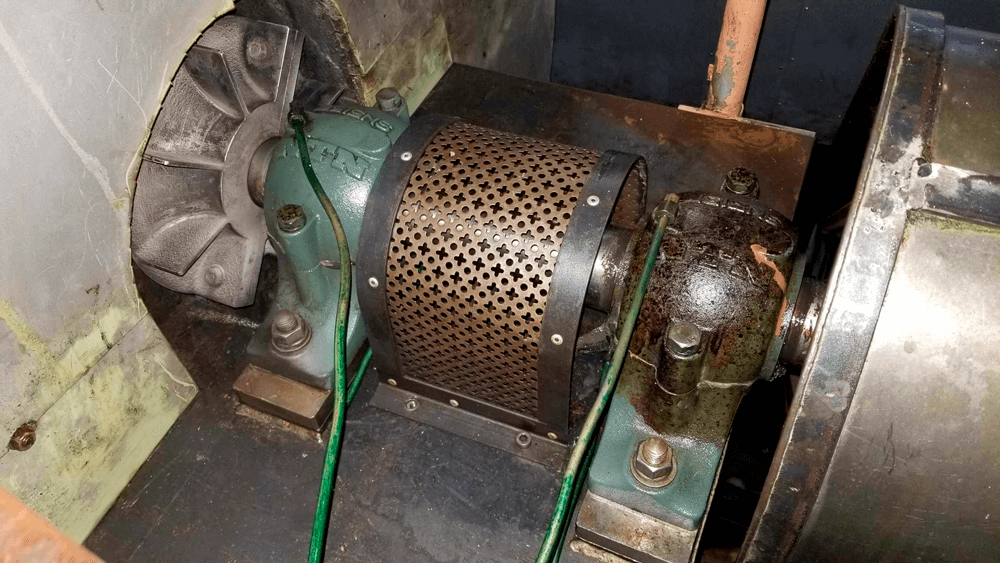

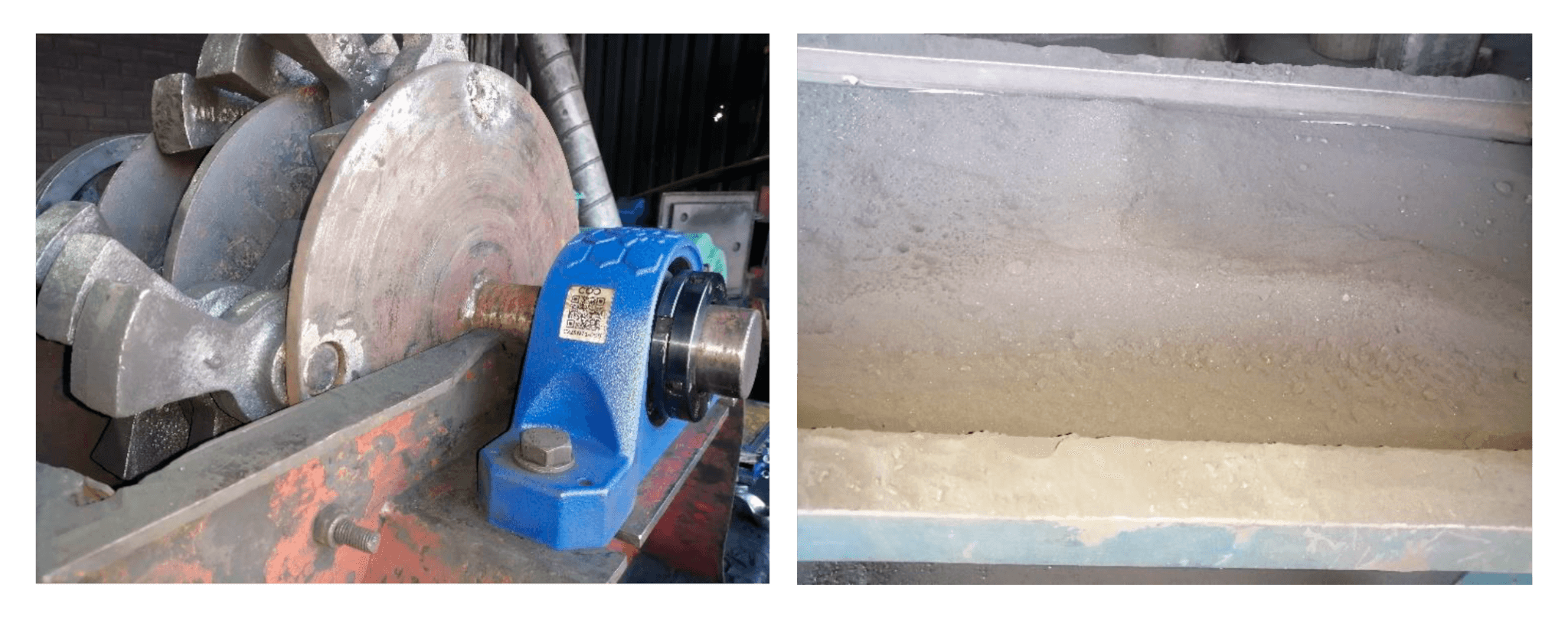

BEFORE

SN515

The surface temperature of the unit rises to 100°C (230° F) within two months of installation. The grease from the unit is changed every two months. The temperature decreases initially after greasing to 80°C (176°F) before starting to rise again.

They cannot change all the grease using a grease gun so they have to take apart the upper part of the housing and clean out all the old grease by hand. This process takes over two hours.

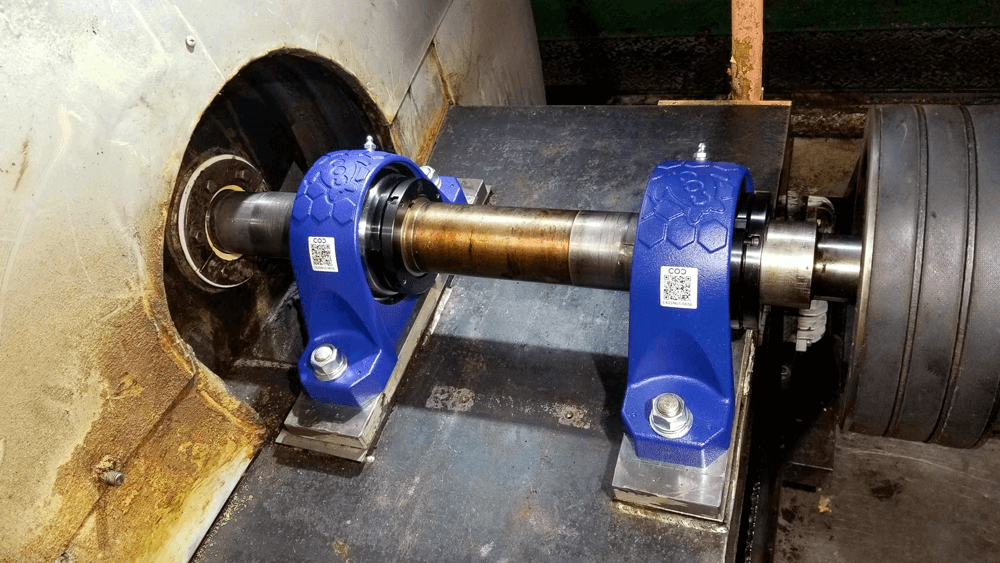

AFTER

CX2SN15-065L

The surface temperature of the units initially went up to 120°C (248°F) and then decreased to 80°C (176° F) after the excess grease was purged within 24 hours. The temperature since then has remained between 65°C (149°F) and 80°C (176°F).

They don’t need to worry about the temperature any more. The COC unit saves money in downtime, labor and the cost of the grease.

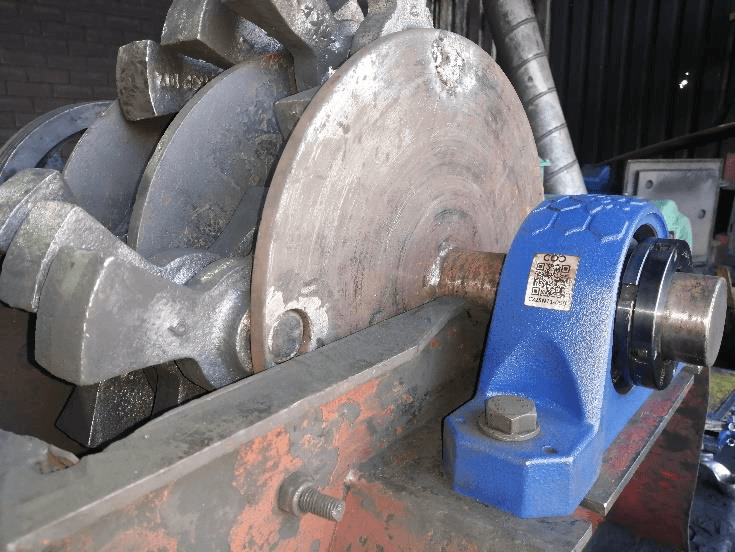

This Coal Pulverizing Hammer Mill application exposes the bearing to extreme dusty and vibratory conditions and the 22211 E1 KC3 spherical roller bearings in a standard SNK511 plummer block were lasting between 4 to 8 weeks. The bearings were failing due to the ingress of coal dust in the bearings.

Our two CX2SN11-050 bearings ran perfectly from the 1st of October 2020 to 7th of June 2021. The COC bearing lasted 8 months with easy installation and removal versus 1.5 months of operation with difficult installation and removal.