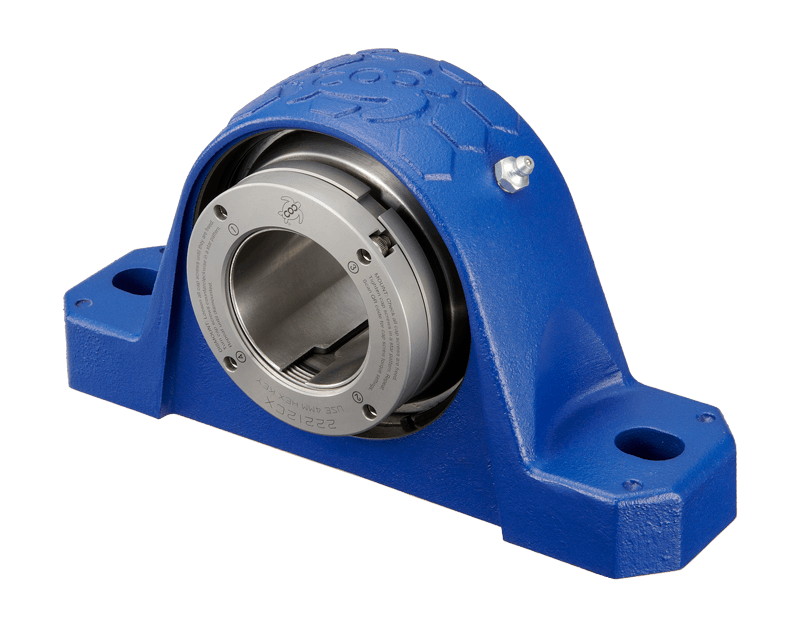

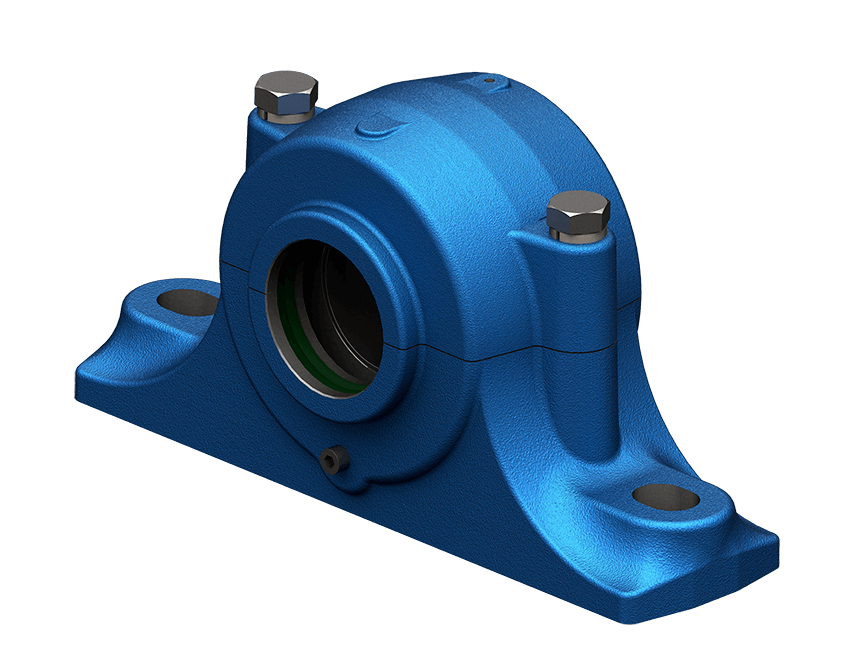

CX2SN vs. SN500

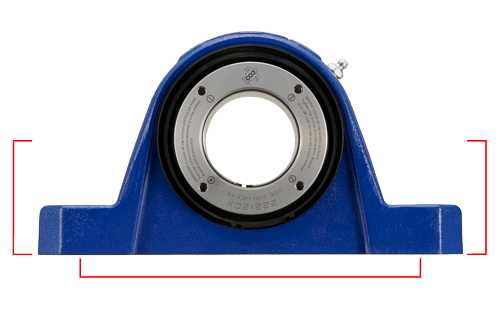

SAME DIMENSION

SAME O.D. SIZED BEARING

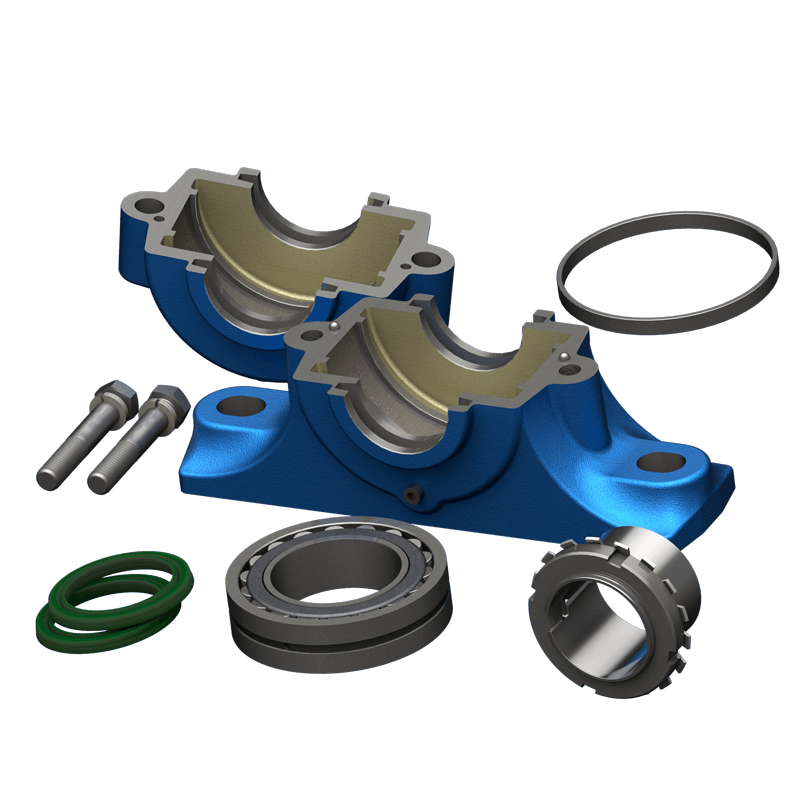

Ready-to-mount unit

PRODUCT

User assembled

Only one part to order

ORDER

Three or more to order

Triple lip seal contacts with the stainless steel flinger, not the shaft or inner ring. It has constant seal pressure in misaligned conditions.

The grease in CX2SN bearing purges depending on the speed of application. As the RPM’s increse this seal allow the excess grease to excape allowing it to run at lower temperatures.

SEAL

The seal lip rubs against the shaft which leads to damage to the shafting. Diminished seal pressure can also occur when there is misalignment.

The SN bearing has a larger void meaning more grease is needed. The seal design of the SN bearing does not allow excess grease to purge easily meaning that it continually runs at a higher temperature.

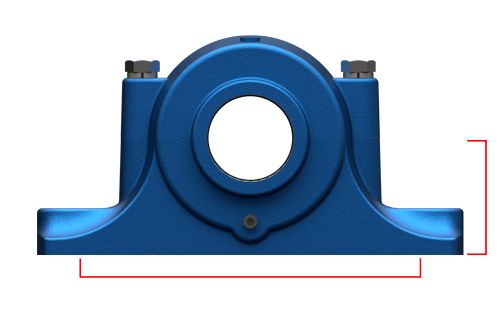

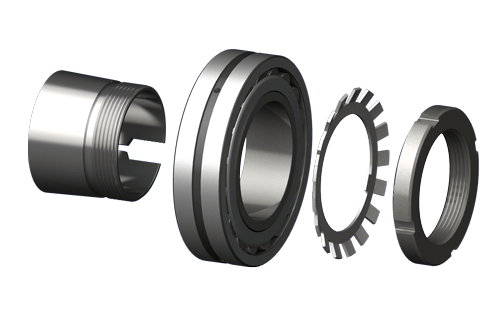

CROSSLOC™

Holds with a long sleeve.

LOCKING STYLE

ADAPTER

Holds with a short sleeve.

EASY

- Tighten cap screws in star pattern to lock

INSTALL

DIFFICULT

- Check the clearance with feeler gauges

- Tighten lock nut until the appropriate clearance in chart

- Bend a tub of lock washer

EASY

- Loosen cap screws in star pattern to remove

REMOVE

DIFFICULT

- Untighen lock nut and hit with hammer to remove

- Or Use pulley puller to remove

Hex key

Torque wrench (recommended)

No bending a tab or marking on the nut.

TOOLS

Spanner wrench

Hammer and drift

Feeler gauges and charts

Factory greased and sealed

LUBRICANT

User has to buy and pack grease.

Needs 4 times more grease than CX2SN because SN has a larger void.

Lower total cost of ownership

SAMPLE OF COST COMPARISON BETWEEN CLASSIC SN & CLOSSLOC™ SN

- Cost of classic SN (Total of Plummer Block + SRB + Adapter + Locating Ring + Seals + lubricant) 78%

- Cost of CROSSLOC™ SN (One piece complete unit of sealed bearing with CROSSLOC™) 100%

- Skilled Labour Cost of Mounting classic SN (Assembling parts and installing adapter sleeve with lubricant) 25%

- Cost of Mounting CROSSLOC™ SN (Tightening Cap Screws without skills) 3%

- Skilled Labour Cost of Dismounting classic SN (Disassembling parts, cleaning lubricant and uninstalling adapter sleeve) 21%

- Cost of Dismounting CROSSLOC™ SN (Un-tightening Cap Screws without skills) 2.5%

COMPARISON OF GREASE INITIAL AMOUNT

- SN517 Plummer Block Unit (500 g) 100%

- CROSSLOC™ CX2SN17-075 (132 g) 26%

Using less oil helps the environment.